China Supply 200W Gold Silver Jewelry Spot Welding Machine Price

| Category | Auto Laser Welding Machine |

| Model No. | BE-W200F |

| Views | 38070 |

| Rating | ★★★★★4.5/5 Based on 600 Votes |

| Price Range | US$3500-US$3999/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time | 7-15 Days |

| Shipping | Air/Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Gold and silver jewelry spot welding machines are a vital tool for any jewelry maker. These machines provide an efficient and effective way to join metal pieces together, allowing for a wide range of designs and styles. They offer a number of benefits, including increased strength, stability, and precision. This machine is capable of welding gold and silver pieces of jewelry at a faster rate than traditional methods, as well as providing precise and accurate results.

Investing in a gold silver jewelry spot welding machine can be a great way to save money and time when crafting jewelry. Not only can spot welding make the process of creating jewelry faster and easier, but there are also a variety of other benefits that come with owning one of these machines.

Good Features

- It features a continuous operating capacity of 24 hours and a low power usage.

- On the basis of a 10x microscope, a CCD monitoring system can be incorporated.

- The heat affected zone is minimal, and the size of the welding area can be modified at whim.

- The welding points are flat and elegant.

- The display screen is a 7-inch LED screen that supports Chinese, English, Russian, Spanish, and other languages, as well as an air blowing protective device.

- It can give tailored, individualized services.

Parts Introduction

Machine Design

- Europe ergonomics design

- It has a open large inner working space that allows for a flexible angle of human hands.

- It is practical to store tools or fittings within.

Built-in Water Cooling System

- Powerful cooling effect which ensures the machine 24 hours continuous work. Peak power reach 220W.

- Installed with a top China brand constant temperature industrial water cooling system that can automatically regulate the temperature.

Rolling Wheel

- Easy to move the machine freely

- Wear resistant and long service time

Controlling Screen

- It uses a built-in controlling system with a touch screen to ensure great sensitivity and easy parameter configuration.

- Users can configure many settings (current, frequency, pulse, etc.) based on the material. Parameters can be saved.

CCD Camera+Display Screen

- Operator can observe the welding details from the screen, which ensure the welding high precision.

- The CCD screen and controlling screen integrated into one, which simplify the operation.

Observation Microscope

- It employs a high-precision (10X) microscope from China, allowing for precise positioning and welding.

- The operator can plainly watch the welding process, ensuring high accuracy welding.

Switch Button

- Simplify the operation process and ensure safety by separating the buttons’ functions.

- Red urgent button for emergency use. Key switch for starting the machine.

Gas Pipe

- To achieve clean welding, Argon gas must be blown over the welding surface.

- The gas blowing direction should be adjusted according to the welding position.

LED Lights

- The brightness of the led lights can be adjusted by the operator to ensure eye comfort.

- High brightness, long lifespan, energy savings, and simple installation.

Joysticks

- Scientific design improves the performance.

- It can help change the parameters by using the joysticks, without pressing on the screen, saving manual work and increase efficiency.

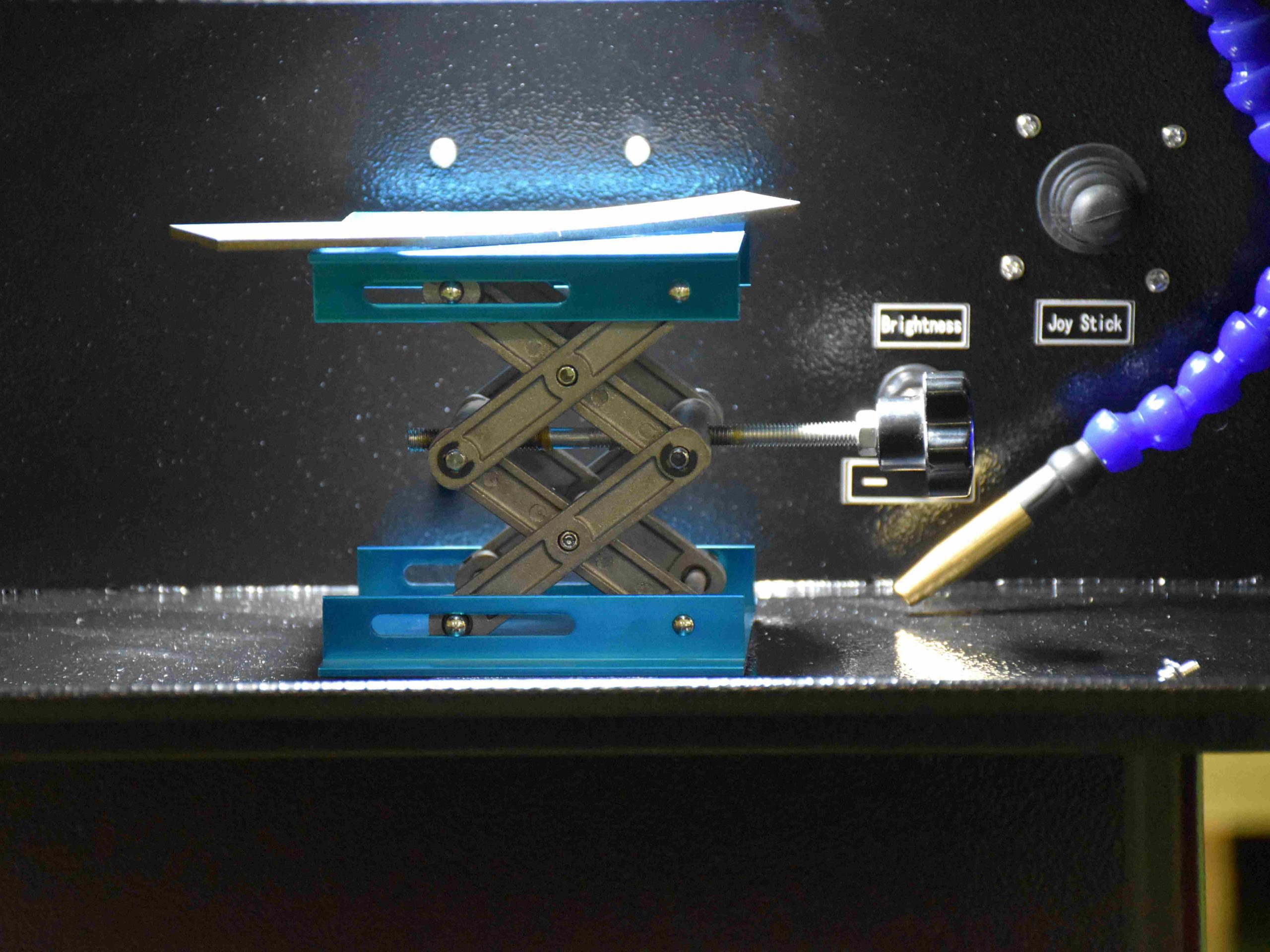

3D working table

- High quality alloy made, anti-corrosion and anti-rust.

- 3D adjustment, and helpful for focusing the laser beam if placing the object on the table.

Electric/Gas Ports

- Electric and gas ports with safely cables and clear tips.

Foot Pedal

- Pressing on the foot pedal to control the laser output

Application

Gold, silver, platinum, stainless steel, titanium, and other metals and alloys are used in welding. It is commonly used to repair holes in gold and silver ornaments, rings, pendants, bracelets, and necklaces, to spot weld sand holes, to patch seam lines, and to weld the claw corners of inlaid pieces, among other things. It can also be used to fix sand holes in dentures as well as to weld small and precise pieces (such as battery nickel strips, inherited circuit leads, watch hairsprings, picture tubes, electron gun assemblies, etc.).

Jewelry spot welding machines are essential tools for jewelry makers and craftsmen. Spot welders make it possible to join pieces of metal together securely and quickly. They provide an efficient and reliable way of connecting components in jewelry making, both in terms of strength and aesthetics.

| Model | BE-W200F |

| Power | 200w(peak power 200w) |

| Wavelength | 1064nm |

| Power Consumption | 3KW |

| Pulse Energy | 100J |

| Laser Focus | 110mm |

| Pulse Frequency | ≤0.1-20Hz |

| Pulse Width | ≤15ms |

| Protection Gas | Single |

| Voltage | 220V/110V |

| Observation System | Microscope 10X + CCD camera |

| Cooling | Inner Water Cooled |

| Controls | Touch Screen or Joystick |

| Language | Chinese/English |

| Protective Gas | Argon |

| Dimension | 1.23*1.08*0.59M |

| Net Weight | 120kgs |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W200F | 1.34M×1.14M×0.63M, 0.96CBM | 200KG |

|

|

|

| Inside layer is covered by thickening plastic bag and foam for waterproof. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

Carlos enrique mejia boer

★★★★★Post a review on Aug 21, 2022 From Mexico

The welding seam is quite attractive, and it can repair various types of damage. Very helpful!

-

Alexandr Perkanuk

★★★★★Post a review on Aug 21, 2022 From Russian Federation

Welded flawlessly. It can fix a variety of jewelry. Everything is running smoothly.

-

talleresvisocar limens

★★★★★Post a review on Aug 21, 2022 From Spain

The result is really pleasing, and the welding seam is very thin.

-

M van Steen

★★★★★Post a review on Aug 21, 2022 From Netherlands

It is really potent. Thank you for your patience in explaining, and we look forward to future use.

-

Danilo Jovetta

★★★★★Post a review on Aug 21, 2022 From Brazil

BST was recommended to me by a friend for gold and silver jewelry processing. Laser welding is ideal for jewelry processing because of its low cost.