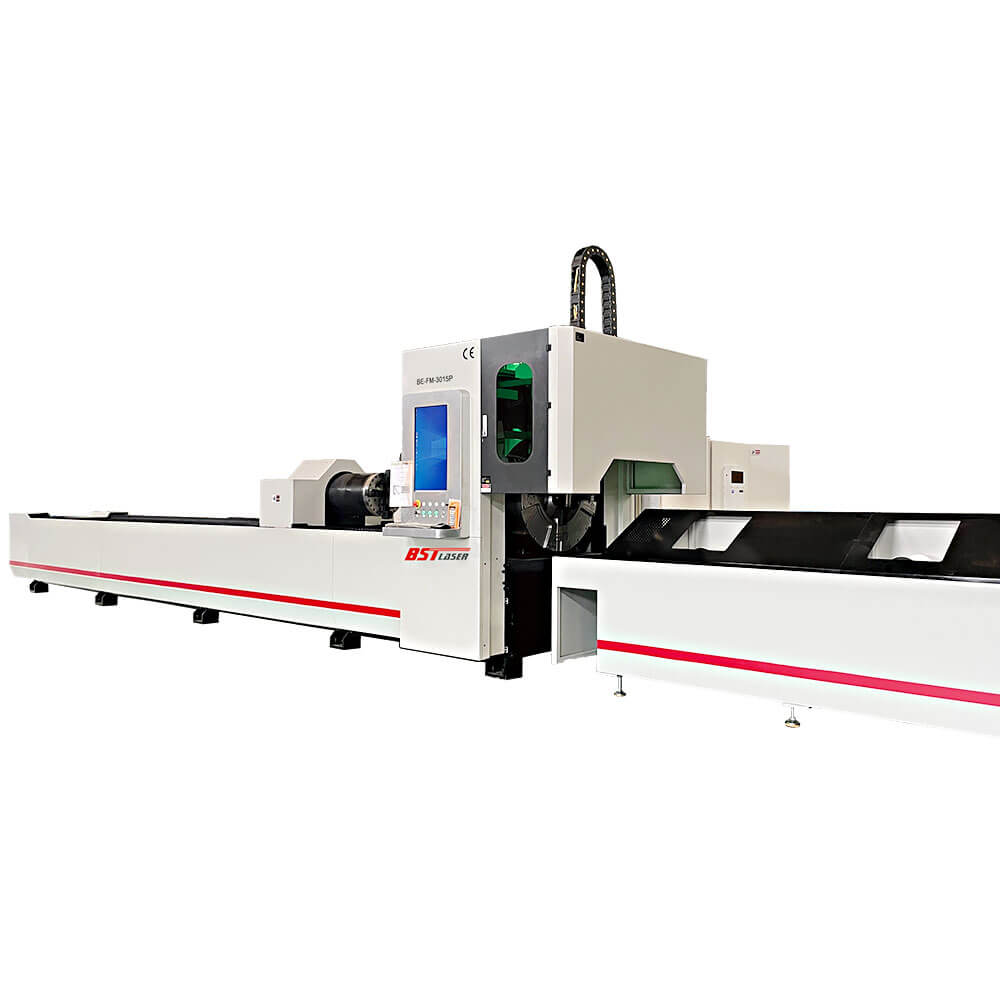

All Cover Exchange Table Metal Laser Cutting Machine

| Category: | Fiber Metal Laser Cutting Machine |

| Model No.: | BE-FM-3015XC |

| Views: | 3800 |

| Rating: | ★★★★★5/5 Based on 5200 Votes |

| Price Range: | US$20,000 – US$50,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer |

| Leading Time: | 40-60 Days |

| Shipping: | Sea Shipment |

| Warranty Period: | 36 Months for Machine and 24 Months for Fiber Laser Device with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Metal laser cutting machines are becoming increasingly popular for their numerous advantages over traditional cutting methods. These machines can cut thick and thin metals with accuracy and precision and can be used for a wide range of applications. The machines are fast and easy to use, and require minimal setup and maintenance, making them cost-effective for businesses.

Loading and unloading are more convenient and efficient with the Double Exchange platform, which is appropriate for large metal plate high-precision processing.

STANDARD COMPONENTS

◆ CYPCUT®FSCUT2000 CNC Control System

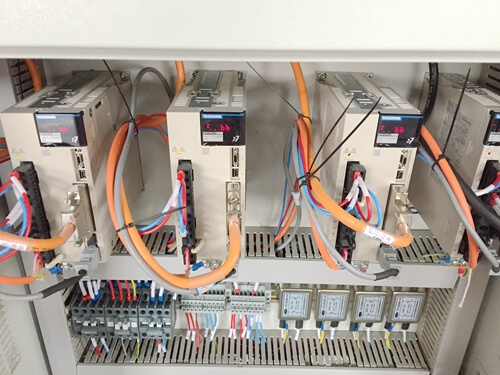

◆ Fuji®High Dynamic EtherCAT servo drive

◆ BSTLASER®Dynamic System 4.0:1.5g Acceleration

◆ BSTLASER®Fast Piercing 2.0:Ultra Performation

◆ Automatic Table Exchanger 3015 (Optional 4015,4020,6015,6020)

◆ Smoke Extraction Fan System

◆ Graphite Anti-burn Technology

◆ Fiber Laser Source Raycus 3000w 4000w 6000w 12000w

◆ Class IV safety system and CE marking

◆ CYPCUT®Embedded Pcs: Industrial PCs with directly integrated I/O level

◆ Hiwin®high performance and high accuracy rack and pinion system

Metal Cutting Capacity

| Laser Power | 3000W | 4000W | 6000w | 10000W | |

| Nominal power | kw | 3 | 4 | 6 | 10 |

| Power requirement | kw | 10 | 13 | 19 | 32 |

| Wavelength | nm | 1074 | 1074 | 1074 | 1074 |

| Carbon steel | mm | 22 | 25 | 25 | 30 |

| Stainless steel | mm | 10 | 12 | 20 | 28 |

| Aluminum Alloys | mm | 8 | 10 | 16 | 26 |

| Brass | mm | 6 | 8 | 12 | 15 |

Machine Feature:

- With strong adaptability, flying cutting speed, a high degree of stability, high-quality processing, and strong cutting ability

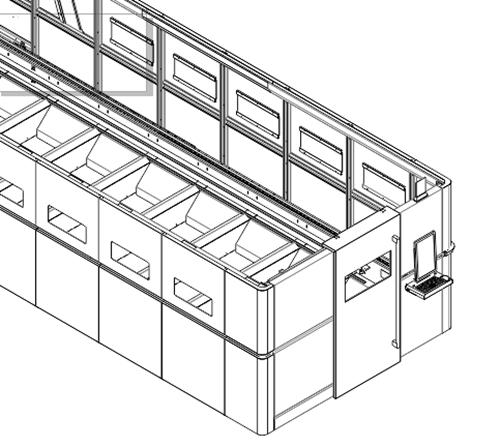

- Adopt a parallel interactive working table that is entirely encircled by sheet metal outside protection and is Metal mechanical equipment with better performance and cost performance.

- A higher part count and first-class foreign components significantly enhance machine cost performance.

- A particular machine is created with supporting ribs in the center of the bed to extend the life of the bed.

- To ensure both user safety and environmental protection, the entire machine is designed with a massive enclosure.

- With an integrated industrial LCD touchscreen, you can effortlessly set the parameters and save space.

Parts Introduction

Full Enclosed Cover Cabinet

- The electric cabinet is integrated with the machine body to occupy the reduced area, such a fully-sealed structure and standard electric wires can prevent dust entry and harmful burning.

- Equipped with CE safety protection glass safety window and interlock design that closely adheres to European safety regulations.

Aviation Aluminum Casting Gantry

- It is constructed with aerospace standards and formed by press extrusion molding. Its strength can increase dramatically after age therapy.

- Aviation aluminum has numerous advantages: good toughness, lightweight, corrosion resistance, anti-oxidation, and substantially raise processing speed.

Heavy Duty Welding Bed

- Using the most popular welding structure for heavy-duty steel plates with great stability. The structural materials undergo high-stress relief annealing and natural aging treatment to eliminate internal tension, it can keep the machine for 50 years without distortion.

- The addition of four supports and reinforcing ribs inside the tube ensures high-speed operation without shaking.

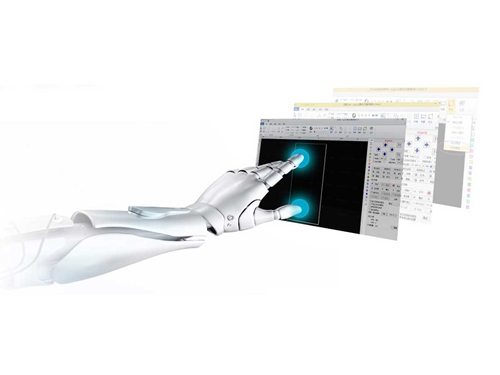

Intelligent Controlling System

- The CypCut controlling system is designed specifically for controlling laser-cutting machines, making it incredibly convenient and practical. When used in conjunction with a laser cutting machine, it may produce the greatest metal-cutting processing results.

- Various graphic formats, including AI, DXF, PLT, Gerber, LXD, and international standard G codes produced by programs like Master Cam, Typer3, and Wentai, are supported.

- Supports segmented piercing, progressive piercing, pre-piercing, grouping, and pre-piercing, as well as allowing the individual adjustment of laser power, frequency, laser form, gas type, air pressure, peak current, delay, follow height, etc.

Transmission System

- Taiwan YYC grinding grade rack& Taiwan PMI/Hiwin high precision linear square track (Original Genuine)

- It ensures rapid cutting speed with very accurate location and long service life.

Auto Focusing Laser Cutting Head Raytools

- Easy maintenance modular design.

- Auto focus to reduce human intervention and enhance piercing and cutting efficiency.

- 3 Cover the top, center, and bottom of the glasses to preserve the focus and collimation lenses.

- IP65 dustproof, patented cover glass cover plate.

- All-around dust protection.

- Fiber Interface: QBH, QD, and G5

- Speed: 170mm/s, Accuracy: 50um

- Collimation Side (Top)24.9*1.5mm-,Focusing Side (Bottom/Middle)27.9*4.1mm

- Assistant Gas: ≤30bar,Weight: ~5.7kg

Japan Imported Servo Motors

- Original Japan AC Servo Motor with Driver-7 series.

- The ability to achieve extremely precise positioning with an imported servo system is ensured by its excellent dynamic response acceleration characteristic and closed-loop, control approach, which allows moving positioning mechanisms to run smoothly, dependably, and without the need for maintenance.

Reducer

- Shimbo reducer from Japan.

- Output through flange.

- Accuracy and stability life are greater than ten times that of the shaft output Grade 3 accuracy.

Cooling System

- S&A CWFL series is a top China brand with a variety of alarm protection functions.

- It operates in two modes: constant temperature and intelligent temperature management.

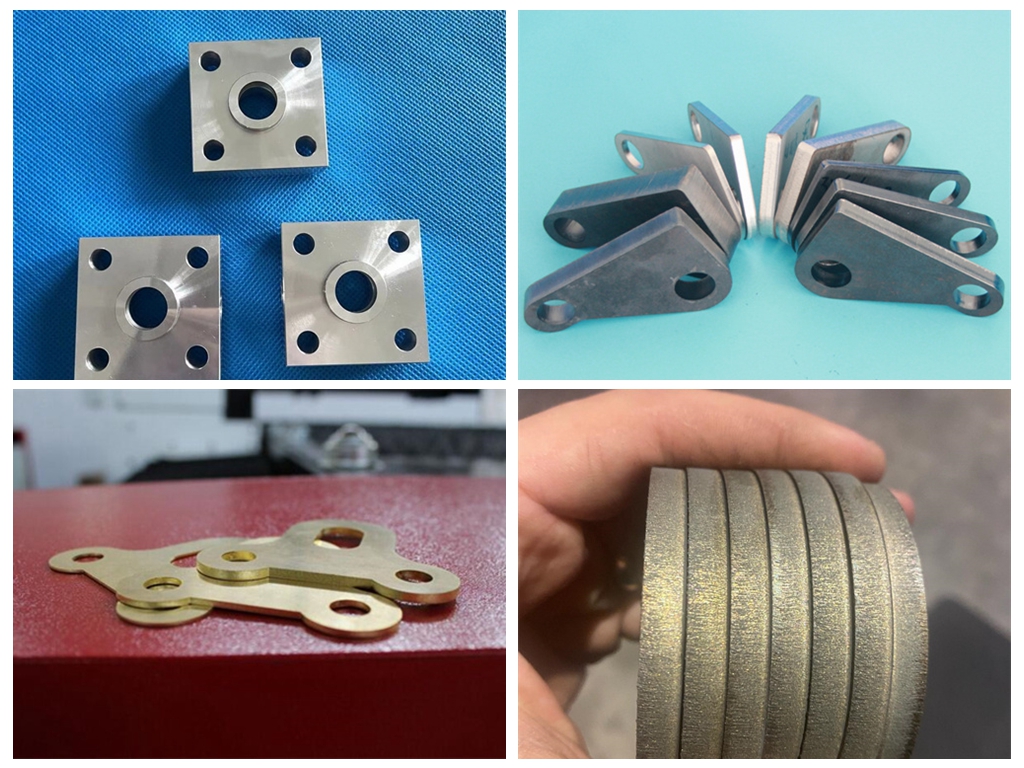

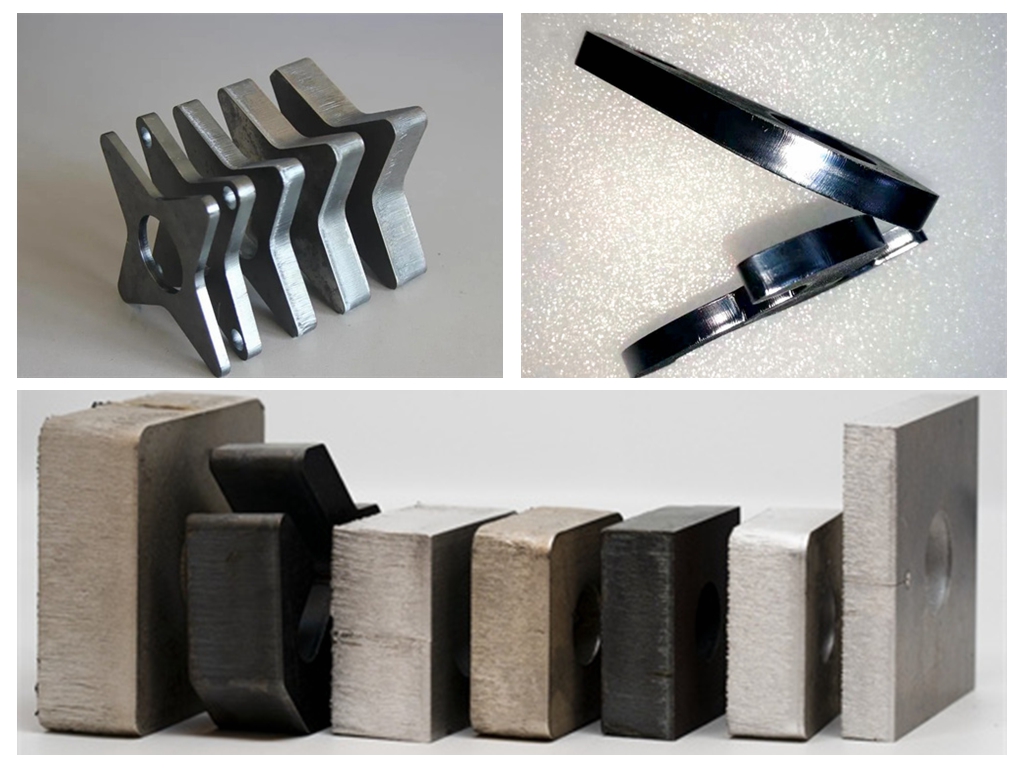

Application

Metal laser cutting machines are an essential tool in any metalworking shop. They offer a wide range of advantages over traditional cutting methods. These advantages include greater precision, speed, and efficiency, as well as improved safety for both the operator and the material being cut. They are also cost-effective, as they require less material to achieve the same quality cuts.

Relevant Industries

Railway transportation, shipbuilding, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen and bathroom, decorative advertising, laser external processing services, and so on.

Application Materials

Carbon steel, stainless steel, aluminum alloy, brass, copper, pickling sheet, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy and other metal materials.

Optional Items

| Model | BE-FM-3015XC |

| Working Size | 1500×3000mm |

| Laser Power | 4000w 4000W 6000W 10000W |

| Laser Source | Raycus (Optional: Max/JPT/IPG) |

| Optional Size | 4000×1500mm/6000×1500mm/6000×2000mm |

| Max. Cutting Speed | 30-50 Meters / Min (up to materials) |

| Max. Location speed | 60m/min |

| Laser wavelength | 1070nm-1080nm |

| Minimum line width | ≤0.1mm |

| X/Y Location Accuracy | 0.03mm |

| Re-location precision | ±0.02mm |

| Max Acceleration | 1.5G |

| Max. moving speed | 100m/min |

| Supporting Format | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc |

| Power demand | 3 PHASE AC 380V 50HZ/60HZ |

| Working Table | Exchanging Working Table |

| Worktable max. load | 6000KGS |

| Transmission Method | gantry type double rack servo drive |

| Table-driven system | Japanese Imported Servo Motor & Driving System |

| Focus Method | Following and Automatic Adjust Focus |

| Control software | Cypcut |

| Working Environment Temperature | 0℃~45℃ |

| Working Environment Humidity | 5%~95% non-condensing |

Package and Shipment

| Model | Machine Size Dimension | Gross Weight |

| BE-FM-3015XC | (8040+6700)×3045×2100mm | 6000KG |

|

|

|

| Inside layer is covered by thickening plastic bag and foam for waterproof. | Loading container EXW factory, workers putting machine into container | Send to the named sea port and load in the container |

-

Philip Im

★★★★★Post a review on Aug 21, 2022 From Korea

The design is really attractive but sturdy, and the cutting precision is considerably higher than the big size 3015 that I previously purchased. I fell in love with it at first sight.

-

Vardan Avetisyan

★★★★★Post a review on Aug 21, 2022 From Armenia

After comparing several manufacturers, I decided on BST LASER, which did not disappoint. The quality of the machine is extremely nice. After-sales service is also excellent.

-

Eduard Gepting

★★★★★Post a review on Aug 21, 2022 From Germany

All issues have been resolved; we may require some technical assistance during testing, but everything is now operational and the cutting is excellent.

-

sky pub

★★★★★Post a review on Aug 21, 2022 From Algeria

I’ve had this machine for a long time and it works flawlessly. The after-sales support is also very good, able to address the installation and debugging problems in time. Professional assistance!

-

Ricardo Dominguez

★★★★★Post a review on Aug 21, 2022 From Mexico

This machine appeals to me. It brings me a continual stream of shocks.

Thank you very much.

Excellent experience.

-

Jose Eduardo Paris Muñoz

★★★★★Post a review on Aug 21, 2022 From Brazil

We represent laser cutter machines in Brazil, and this is our second purchase. The quality and service were both excellent!! Already ordered 5 sets again.

I’m looking forward to greater collaboration!