Tabletop Fiber Laser Welder for 3D Metal Letter

|

Category |

Auto Laser Welding Machine |

|

Model No. |

BE-W1500L /BE-W2000L |

|

Views |

25380 |

|

Rating |

⭐⭐⭐⭐⭐ |

|

Price Range |

US$4000–US$7800/Set |

|

Payment Term |

T/T Bank Transfer, Western Union, Paypal |

|

Production Time |

7-15 Days |

|

Shipping |

Air/Sea/Train/Truck |

|

Warranty Period |

Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Brief Introduction:

Are you still used traditional YAG laser welder for making the 3d metal letters ? Now it’s the time to say goodbye ! BST LASER new launched Tabletop Fiber Laser Welding Machine adopts the fiber laser device as the laser generator which can be used for welding all kinds of metals like stainless steel,aluminum,galvanized sheet,iron,etc. Small running costs,excellent welding effect and free of maintenance ,totally solved the shortcomings of YAG laser,perfectly help the clients in sign and advertising industries improve their efficiency 100% .

Technical Features :

1.Equipped with a latest-generation fiber laser, dual-oscillating welding head with multi-spot mode, dual-temperature dual-control adaptive intelligent chiller system, high-definition CCD targeting and positioning system, integrated workstation cabinet, and mobile positioning unit.

2.Advanced Ergonomic Control System:

- Features a foot-pedal switch and adjustable positioning device, integrated with a dual targeting system (red laser + CCD imaging) for precise alignment.

- Enables multi-limb coordination (hands, feet, eyes) to optimize workflow efficiency.

- Ergonomic sit-stand workstation design reduces operator fatigue and enhances comfort during prolonged operations.

3.High-Performance Laser Source & Welding Optics:

- Utilizes a stable continuous-wave (CW) fiber laser with industry-leading reliability and output consistency.

- Dual-oscillating welding head with multi-spot mode offers adjustable spot geometry (shape/size), expanding tolerance compatibility for diverse components and weld seam widths while ensuring superior weld consistency.

4.Process Advantages:

- High-speed, maintenance-free operation with consumable-free process.

- Delivers aesthetic weld seams with no post-weld discoloration, deformation, or surface marks, eliminating post-processing grinding.

5.Energy Efficiency:

Low power consumption paired with a high energy density beam ensures precision welding with minimal thermal input..

Parts Introduction

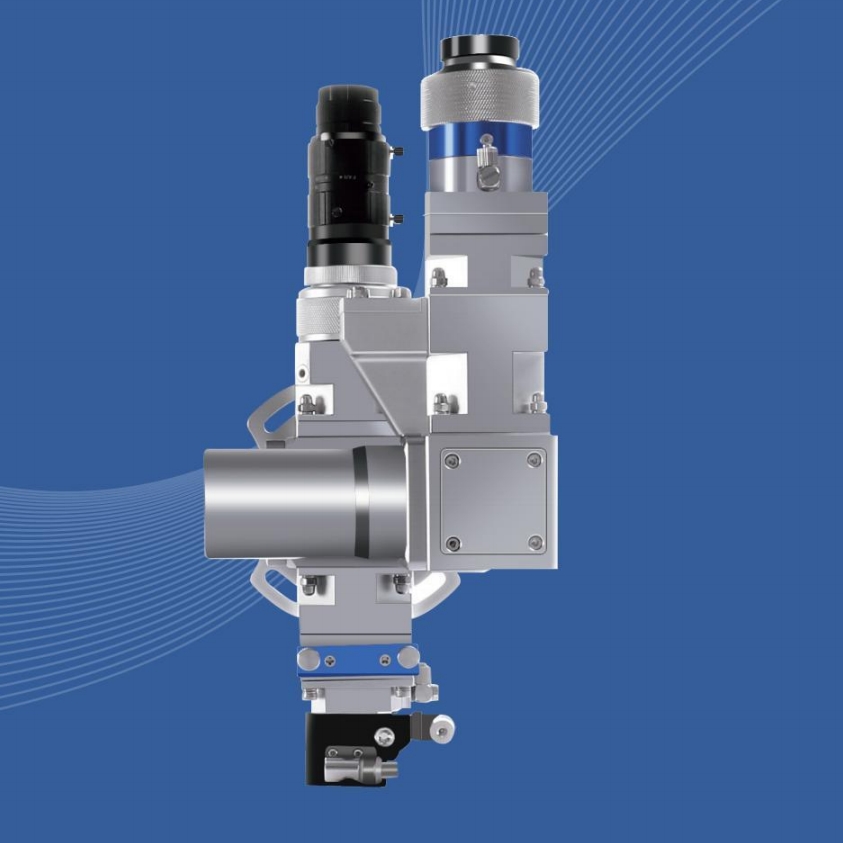

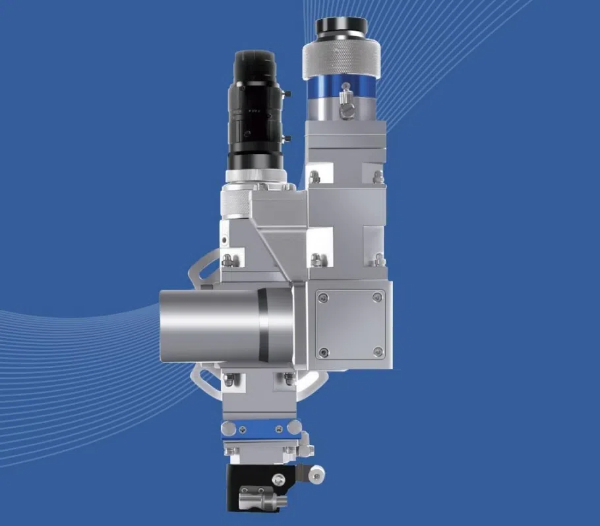

Dual-oscillating Welding head

- This welding head demonstrates exceptional advantages in aluminum alloy welding and low-power laser welding applications, offering a cost-effective solution.Equipped with motor-driven X/Y-axis galvanometer scanners, it supports multiple oscillation modes to ensure high-quality welds on irregular seams and accommodate larger joint gap.

- Equipped with motor-driven X/Y-axis galvanometer scanners, it supports multiple oscillation modes to ensure high-quality welds on irregular seams and accommodate larger joint gap.

- Integrated with an air curtain and coaxial gas assist system, it effectively minimizes welding spatter and fumes deposition on lenses.

-

The welding head is compatible with various laser sources featuring QBH interfaces, ensuring broad adaptability across industrial laser systems.

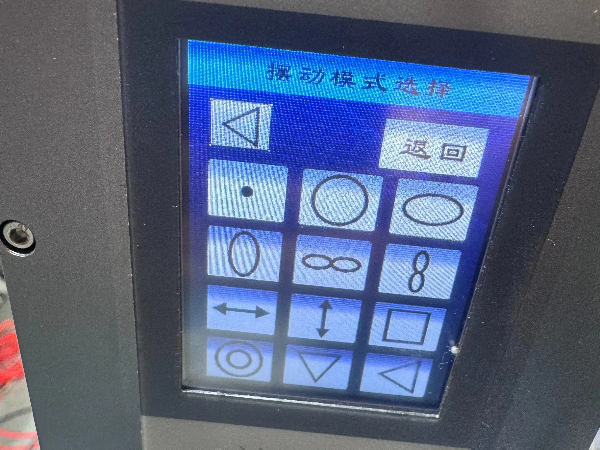

Multi Spot Welding Mode

The system support 12 different kinds of welding mode,you can choose the suitable welding modes when welding on metals in different shapes and joints.The system’s ability to support diverse welding modes significantly enhances operational flexibility and process efficiency.

Support 8 Different Languages

The standard system currently support 8 language like Chinese,English,Spanish,Russian,Vietnamese,Arabic,Japanese,Korean. Other languages can be also customized if order in batch .

Controlling PC&Observing Screen

- Dual temperature and dual control adaptive intelligent chiller,which can effectively cooling the laser parts during heavy processing production.

-

This advanced chiller architecture transforms thermal management from a passive support function into an active process-enabling technology, directly contributing to ≤0.1% scrap rates in high-volume EV battery tray welding applications.

Application

Desktop fiber laser welding machines outperform traditional YAG systems in efficiency, cost-effectiveness, and processing precision. With negligible consumables, low energy consumption, and minimal maintenance, fiber lasers reduce total cost of ownership (TCO) while delivering superior weld quality and throughput. YAG technology, though once dominant, is increasingly obsolete for high-volume, precision-critical applications in industries like electronics, automotive, and medical device manufacturing,sign and advertising industry .

|

1 |

Model |

BE-WF15000 |

BE-W20F00 |

|

2 |

Power |

1500W |

2000W |

|

3 |

Wavelength |

1080NM±5nm |

|

|

4 |

Energy Fluctuation |

<1.5% |

|

|

5 |

Operating Mode |

Manual |

|

|

6 |

Fiber Output Number |

1PCS |

|

|

7 |

Fiber Connection |

QBH |

|

|

8 |

Welding Head |

Dual-oscillating (Multi-spot) |

|

|

9 |

Position |

Red Pointer/CCD |

|

|

10 |

Power Consumption |

5KW |

|

|

11 |

Working Temperature |

10 °-45 ° |

|

|

12 |

Working Voltage |

AC220V±5% 50HZ/60HZ |

|

|

13 |

Size Dimension |

2300*900/1400*1150MM |

|

Package and Shipment

|

Model |

Package Size |

Gross Weight |

|

BE-WF1500 |

160cm×107cm×135cm,2.311CBM |

580kg |

-

Electronics Manufacturing Co.,

★★★★★Post a review on From Germany

Switching to the desktop fiber laser welder has drastically cut our energy bills. Its low power consumption outperforms our old YAG system by over 60%, with no compromise on weld quality. The ROI was evident within the first year!”

-

Medical Device Supplier

★★★★★Post a review on From USA

“The zero-consumable design and solid-state laser source have eliminated costly spare parts like lamps or filters. We’ve had no unplanned downtime in 18 months—just routine lens cleaning. Service costs are practically nonexistent!”

-

Aerospace Subcontractor

★★★★Post a review on From France

The manufacturer’s remote diagnostics and responsive technical team resolved a software glitch in under 2 hours. No on-site visits, no extra charges—just seamless support.”

-

Semiconductor Fabricator

★★★★★Post a review on From South Korea

Our operators love the intuitive interface and ergonomic setup. Training time dropped by 50%, and the adjustable parameters handle everything from thin copper wires to thick stainless steel joints.”

-

Artem Kalinin

★★★★★Post a review on From Spain

Machine is same as seller’s description. Easy to use, no need much skills. Workers can operate the machine after 30 minutes training. It is the right machine we require!