Are Laser Engravers Worth To Buy?

Laser Engravers: What Are They and What Are They Good For?

Laser engraving is a process that uses a focused laser beam to burn away a very thin layer of material. The resulting image is similar to a woodcut or intaglio printing, with the advantage that it can be done on a wide variety of materials with different textures and colors.

Laser engraving machines are used in industrial sectors such as manufacturing, automotive, aerospace, electronics, and medical industries for marking parts of various shapes and sizes. They are also used for personalization purposes on consumer products such as jewelry, watches, and eyewear.

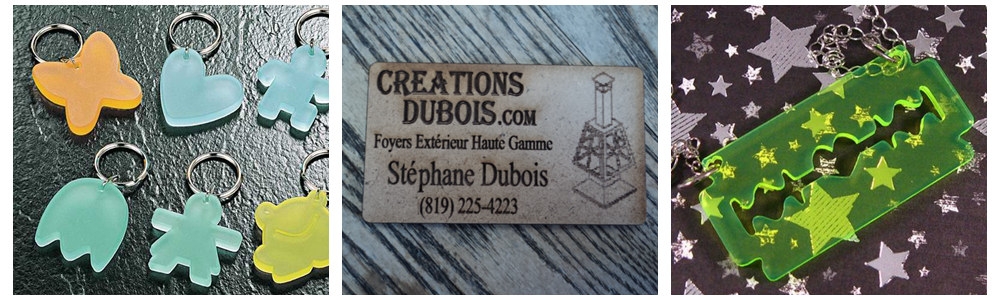

Laser engravers are great for creating intricate designs on metal, wood, and plastic. For example, Wuhan BST Distributor Wanted Compact Co2 Laser Cutting Machine 1390 can also be used to engrave glass and stone. If you want to add an artistic flare to a business card or personalize a wine bottle with your name, then a laser engraving machine can help you do it.

Laser engraving machines are not only used by artists and designers but also by businesses that want to give their products a professional look. For example, many companies use laser engravers to print product serial numbers on their goods so they can easily track inventory.

Buy Laser Engraving Machines: Is It A Good Idea?

So many people are struggling with laser engravers worth buying. Absolutely. Laser engravers are a great tool to have in your workshop. They can be used to cut out logos, lettering, and images on wood, plastic, and even metal. The process is very similar to cutting with a knife but instead of cutting all the way through the material, the laser only burns away layers on top of the surface without actually cutting it. This allows for much more detailed images to be created.

The laser beam moves very quickly and can cut through virtually any material. This means that you can create a finished product much faster than with other methods of engraving or cutting. Laser engravers have been around for many years but they have become much more affordable in recent years and there are many different types available now that you can buy Wuhan BST.

Laser engravers offer you the ability to create custom high-quality pieces of art that can be used for anything from personal projects to business logos. If you are looking for a new hobby or business venture, then Wuhan BST Distributor Wanted Compact Co2 Laser Cutting Machine 1390 may be right up your alley.

If you’re thinking about buying a laser engraving machine and wondering if it’s worth it, here are some things to consider:

- The price of laser engraving machines is not low, so you need to consider whether you can afford this machine before purchasing it;

- The quality of laser engraving machines is different from each other, so you need to choose a high-quality one;

- It is necessary to buy a standard accessory set when buying a laser engraving machine;

- You must choose an experienced company if you want to buy a good product at an affordable price.

Advantages of Laser Engraving Over Other Methods

Let’s continue our discussion about our laser engravers worth buying. Laser engraving is a method of permanently marking a surface with text or an image. It uses a laser beam to burn away the top layer of the material being engraved. The laser beam can cut through most materials, including metal, plastic, glass, stone, and wood. It’s also possible to engrave more than one color into the same area of a piece of material.

Taking Wuhan BST Distributor Wanted Compact Co2 Laser Cutting Machine 1390 as an example, there are several advantages to using laser engraving over other methods:

l More Precise Cutting: The laser beam can be directed very precisely and cuts through the material at a consistent speed. This makes it easy to cut intricate details that would be difficult or impossible with other methods.

l Multiple Colors: A single pass of the laser can engrave multiple colors into the same area of an object. This allows you to create multicolored images without having to apply each color separately.

l Fine Detail: Laser engraving can produce very fine details that are difficult or impossible to replicate with other methods of engraving.

l High Speed: Laser engraving is very fast. A laser can cut through materials that would take minutes or hours with other methods. The process is also very precise since it uses a computer to control the laser’s movement. This means that you can create intricate designs with ease.

l Ease of Use: Laser engraving machines are relatively simple to use, so you don’t need any special training to operate them. They’re also quite affordable compared to other types of laser-cutting machines, which makes them ideal for small businesses and hobbyists alike.

Most Common Uses For Laser Engravers

Laser engravers are a popular tool in industrial design, as they can produce large and intricate designs that are difficult or impossible to replicate by hand. They can be used to etch metal, glass, and even plastic. The most common uses for laser engravers include:

- Wood Cutting – Wood is one of the most popular materials for laser engraving. The main reason why is that it’s easy to work with and it’s very versatile. You can use wood to create signs, plaques, knickknacks, and other decorative items.

- Metal Engraving – Metal is used in many industries and applications such as construction, manufacturing, and transportation. Laser engravers can be used to add text or logos onto metal surfaces such as tools or machinery.

- Glass Engraving – Glass is an excellent material for creating signs and other decorative items because it can be cut into any shape or size with ease. Glass engraving machines also allow you to create complex designs easily which makes them a popular choice among businesses that want to personalize their products or services using laser engraving technology.

- Plastic Engraving – Plastic materials are some of the easiest things to cut using lasers because they have enough give in them to allow the beam through without breaking apart into pieces. A good example of this would be cutting out shapes from plastic sheeting or acrylic materials such as those used in sign shops for neon lights.

Frequently Asked Questions About Laser Engravers

Q1. How does it work?

Laser engravers use high-powered lasers to remove layers of material from the surface of a material. This process is called ablation. The process is completed by sending pulses of light through a lens onto the material being engraved. The pulse contains more energy than can be absorbed by the surface causing it to vaporize and create an opening in the surface layer. The amount of power used determines how deep into the material you can make an impression.

Q2. How do you get started?

Laser cutters and engravers can be complex machines that require careful setup, proper ventilation, and maintenance. If you want to get started with one of these machines, we recommend you can find Wuhan BST Laser Machinery. Wuhan BST offers in-depth services on how to use these machines as well as safety precautions.

Q3. Are Laser Engravers Worth To Buy?

Are Laser Engravers Worth To Buy? Yes! A laser engraver is a valuable tool for anyone who wants to create their own items at home or in their business without spending too much money on materials. It’s perfect for creating signs, labels, and logos as well as many other things!

Q4. What Is The Difference Between Laser Engraving And Other Methods Of Engraving?

Laser engravings are much more precise than other types of metal or wood engraving methods such as acid etching and sandblasting. This means that you will get a much finer detail when using a laser engraver versus other methods.

Q5. How Much Does A Laser Engraver Cost?

The price of a laser engraver varies depending on the model you choose and how large it is. You will also want to take into consideration what accessories come with the machine so that you can determine how much it will cost overall. For example, if you want a machine that comes with software so that you can design your artwork before sending it over to the machine, this will increase the price tag significantly. If you have any questions, please contact Wuhan BST.

Q6. For more information, Wuhan BST is for your help.

If you are looking for a professional and reliable laser engraver supplier, Wuhan BST is the best choice. Wuhan BST has been committed to providing customers with high-quality products and services. Wuhan BST also provides you with the most competitive price and good service.

Conclusion

A laser engraving machine is an advanced digital engraving machine that is used as an alternative to traditional methods of cutting, carving, or burning objects such as wood, plastic, rubber, and glass. The laser beam can cut through materials at high speed and with high precision.

As one of the leading laser engraving machine manufacturers and suppliers in China, Wuhan BST is equipped with a professional factory that can offer you the best products at competitive prices. Welcome to buying bulk laser engraving machine products made in China at low prices from Wuhan BST.