New Laser Technology: Wuhan BST Fiber Laser Engraver

The development of fiber laser engravers has come a long way in recent years. The technology has become more advanced, allowing for higher precision and faster engraving speeds. In addition, the machines have become more affordable and accessible, making them a viable solution for businesses of all sizes.

One of the latest technologies in the field of fiber laser engraving is the integration of smart software and controls. These systems allow for easy control of the engraving process, as well as the ability to store and recall engraving designs for quick and easy repeatability. Additionally, many fiber laser engravers now feature multiple laser heads, allowing for even faster and more efficient engraving.

Another exciting development in the field of fiber laser engraving is the ability to engrave on a wider range of materials, including plastics, ceramics, and even certain types of glass. This has opened up new possibilities for manufacturers and businesses, allowing them to create high-quality, custom-engraved products with ease.

What Is A Fiber Laser Engraver?

Fiber laser engravers are also known as “laser light sources” or “light engines”. This is because they use optical fibers to convert electrical energy into a light beam which is then used to etch materials like steels such as stainless steel, iron, copper, and platinum as well as a variety of metal oxides, ABS, epoxy resin, ink, and engineering plastics are just a few examples.

Fiber laser engravers are state-of-the-art machines that utilize laser technology to etch intricate designs and patterns onto a wide range of materials. These machines have revolutionized the manufacturing and engraving industries, offering a fast, efficient, and precise solution for marking and labeling products.

Fiber laser engravers are a game-changer in the manufacturing and engraving industries. With their advanced technology, ease of use, and affordability, they are an ideal solution for businesses looking to take their product labeling and marking to the next level. Whether you need to engrave intricate designs, and labels, or simply mark your products, a fiber laser engraver is the perfect solution.

How Does A Fiber Laser Engraver Work?

A fiber laser engraver works by using laser technology to etch designs and patterns onto various materials. The machine consists of several key components, including a laser source, a beam delivery system, a focusing lens, and a control system.

The laser source generates a beam of high-intensity light that is then passed through a beam delivery system, which directs the beam to the focusing lens. The focusing lens concentrates the laser beam onto the surface of the material, heating it to a high temperature and causing it to vaporize or melt. This process creates a permanent marking or engraving on the surface of the material.

The control system of a fiber laser engraver is responsible for controlling the laser beam and the movement of the engraving head. This system allows the operator to input designs and patterns, and adjust the laser intensity and engraving speed.

Fiber laser engravers are highly precise and efficient, making them an ideal solution for a wide range of engraving and marking applications. They can engrave intricate designs and patterns onto a variety of materials, including metals, plastics, and ceramics, and are capable of engraving at high speeds, making them a cost-effective solution for large-scale production runs.

Fiber Laser Engraver Pros & Cons: Facts You Should Know

Fiber laser engravers are highly advanced machines that offer many benefits for businesses and manufacturers. However, like any technology, they also have some drawbacks. In this section, we will discuss the pros and cons of fiber laser engravers so you can make an informed decision about whether this technology is right for you.

1) Pros of Fiber Laser Engraver:

Precision: Fiber laser engravers are highly precise machines that can produce intricate designs and patterns with a high degree of accuracy. This makes them an ideal solution for businesses that require precise and uniform markings and labels.

Speed: Fiber laser engravers are capable of engraving at high speeds, making them a cost-effective solution for large-scale production runs.

Versatility: Fiber laser engravers can be used on a wide range of materials, including metals, plastics, and ceramics. This makes them a versatile solution for businesses that need to mark and label a variety of products.

Durability: The markings produced by fiber laser engravers are permanent and resistant to wear and tear, making them an ideal solution for products that will be exposed to harsh environments or repeated use.

Low maintenance: Fiber laser engravers require minimal maintenance, making them a low-cost solution in the long term.

2) Cons of Fiber Laser Engraver:

High cost: Fiber laser engravers are highly advanced machines and can be quite expensive, making them a less accessible solution for small businesses or those on a tight budget.

Complexity: Fiber laser engravers can be complex machines that require specialized training and knowledge to operate effectively. This can be a barrier for businesses that do not have the resources to invest in training and support.

Limited materials: While fiber laser engravers can be used on a wide range of materials, there are some materials that they cannot engrave effectively, such as certain types of glass or coated metals.

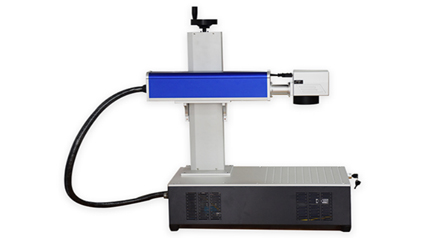

Meet Wuhan BST Mini Small Laser Metal Fiber Laser Engraver, Your New Machine

If you’re looking for a laser engraver that can etch metals, consider Wuhan BST Mini Small Laser Metal Fiber Laser Engraver. This machine is capable of engraving surfaces of many different metals such as gold, brass, and stainless steel.

Any design can be engraved into metal using the machine’s focused beam of light. The fiber laser beam can be used to engrave a variety of materials, including aluminum, stainless steel, copper, brass, and titanium.

Machine Feature:

◆ Long Lifespan: The German-made machine adopts advanced mature fiber optical technology, which makes its lifetime reach over 120,000 hours, greatly increasing service time.

◆ Free of Maintenance and No Consumables: Fiber laser markers require almost no maintenance and have no consumable parts, which saves labor and money.

◆ Easy Operation: No need to adjust laser path, no need for professional skills and just common people can operate after 1-2 days of training, which makes it easy to use.

Bottom Line

Wuhan BST is a professional manufacturer of fiber laser engravers, fiber laser marking machines, and fiber laser cutting machines. Wuhan BST provides high-quality fiber laser engravers according to your requirement. If you need Fiber Laser Engraver, please contact Wuhan BST.