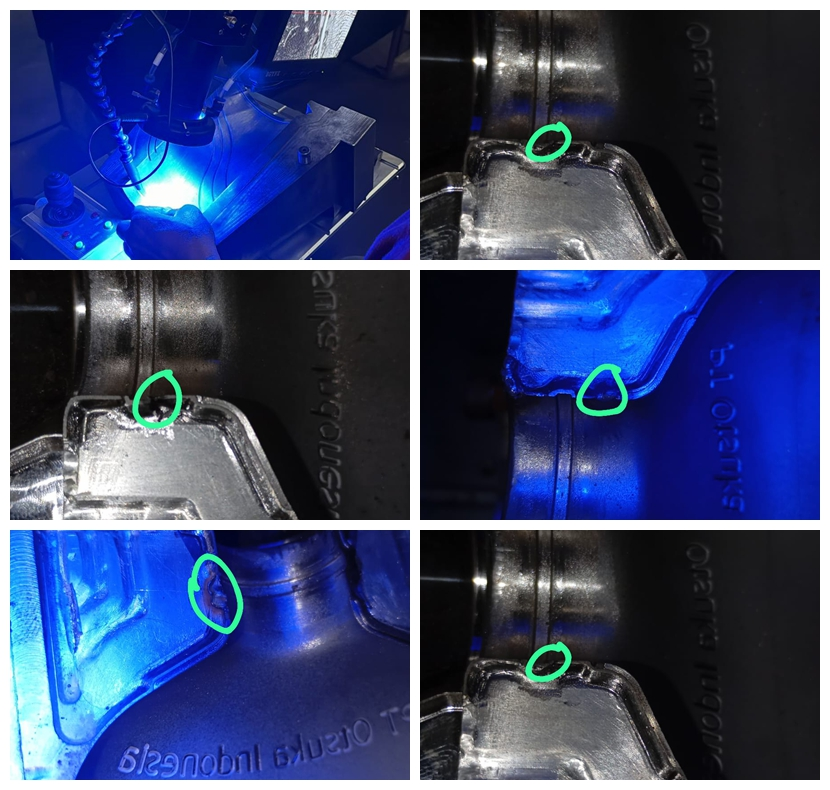

Laser welding machines for mold repair are precision tools widely used in industries such as automotive, aerospace, electronics, and plastics manufacturing. They provide an effective solution for repairing damaged or worn molds, extending their service life, and reducing downtime in production.

BST LASER Offer Below Two Types based on mould size and shapes:

- Standard Laser Welding Machine for Mould Repair :Mainly for the small and medium moulds

- Crane Type Laser Welding Machine for Mould Repair :Applied for Small Mould,Medium Mould and Big Mould More than 100kgs .

There are two below popular model on current market as the different laser generator sources :

- YAG model :(intermittent mode) ,use Nd3+: YAG pulse laser source.

Its main parts include laser light, laser bar, laser pump cavity, optical resonator, cooling system, optical fiber cable and laser welding head.There has 300w 400w and 500w based on the soldering wire size ,bigger power is high welding efficiency will be .

- Fiber Model : Continuous welding mode and spot model.

Which use the fiber laser source as the laser generator,It has the unique advantage of no consumables,free of maintenance ,small welding joint ,no need after-treatment,compact size,small consumption ,easy operation.Even the worker have zero Mechanical operation experience can operate the machine well ,currently there has 1500w and 2000w model .

Both of the two models are the perfect choices for high precision welding on mould .

Currently we recommend clients choose the fiber model although the costs is higher,but it has zero maintenance costs and easy to operate .

If you have the demand of welding moulds,just offer below info and BST LASER team will provide the most professional welding solution :

- What’s the size and weight of your moulds ? (better send pictures to us for reference .)

- What’s the welding soldering dimaeter you always use ? (0.5mm,0.8mm,1mm….)

- Do you need to weld round or cylindrical moulds ? if yes then need the rotary system as optional choices .