300W 400W Metal Mould Repair Laser Welding Machine

| Category | Auto Laser Welding Machine |

| Model No. | BE-W300M/BE-W400M/BE-W500M |

| Views | 65100 |

| Rating | ★★★★★4.9/5 Based on 1000 Votes |

| Price Range | US$3999-US$6999/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 7-15 Days |

| Shipping | Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

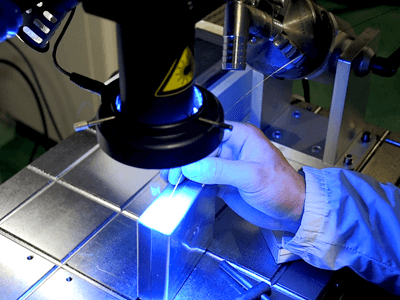

The metal mould repair laser welding machine is an innovative and revolutionary tool that can help to repair and maintain metal moulds quickly and efficiently. This machine uses a laser beam to heat and fuse metal components together, and can be used to repair complex 3D shapes and structures.

It is capable of repairing complex shapes and components quickly and accurately. With its advanced technology, it is also able to make precise and intricate welds. This makes it a valuable tool for any metal moulding shop, as it can help save time and money.

Good Features

- The corrosion-resistant and high-temperature resistant ceramic condenser cavity imported from the United Kingdom has a cavity life of (8-10) years and a xenon lamp life of more than 8 million times.

- The automatic shade system is intended to prevent eye strain while working.

- The upper and lower electric lifts can be pushed forward and backward in addition to the laser head’s 360-degree rotation and that of the entire optical path. It is ideal for fixing various large, medium, and small molds.

- The clever remote controller controls parameter adjustment, which is simple and quick.

- The table foundation is motorized up and down. The table has a ball screw and a linear guide rail, allowing for three-dimensional movement and precise positioning.

- Electric light spot size adjustment.

Parts Introduction

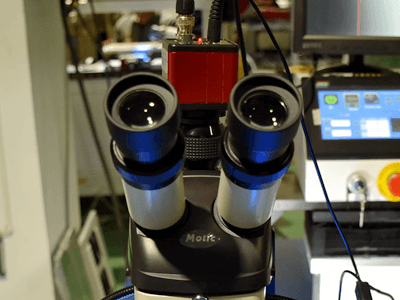

High Precision Microscope

- It makes use of a Chinese high-precision (10X) microscope, which allows for precise positioning and welding.

- The operator can clearly see the welding process, assuring great precision.

CCD Camera and Display Screen

- It may intuitively reflect welding details that human eyes cannot detect.

- Convenient adjustment for light spot size and solder junction position.

Cooling System

- An industrial water chiller helps keep the unit cool and running smoothly.

- The chiller panel’s temperature parameters can be changed by operators. The water chiller is equipped with an air-conditioning system.

(300w-1p,400w/500w-2p)

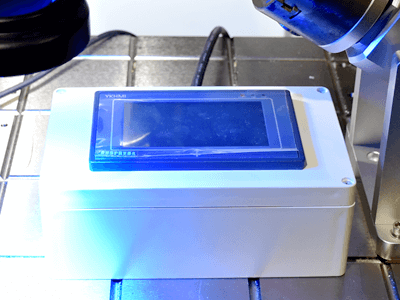

LCD Touch Screen Controller with Built-in Software

- It has a built-in touchscreen control system, which ensures great sensitivity and makes it easy to set up parameters.

- Users can configure many parameters (current, frequency, pulse, etc.) in accordance with various materials. Parameters can be saved.

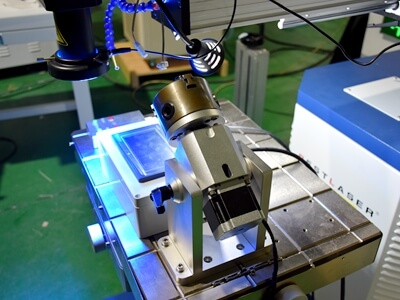

Working table

- Both the electric lift and the manual move in four directions. (in front, back, left, and right) The welding position can be easily adjusted.

- 3D working table with XYZ axis

- The XY movement range is 250*120mm.

Optional Item: PLC Automation

- PLC allows machines to work with automatic gear such as rotary devices, electric moving tables, and robots…

- There’s no need for manual labor. Integrate the welding machine with external equipment using the program.

Optional Item: Rotary Device

- Round objects, such as round heaters, rings, and tubing, can be worked on by the machine thanks to its rotational device, which has an 80mm diameter.

- It is powered by a step motor and outperforms manual labor.

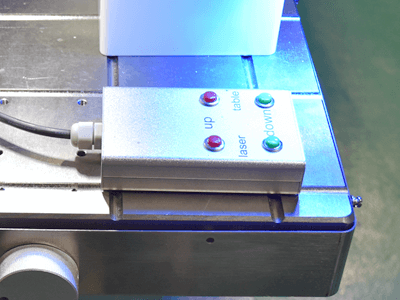

Remote Control

- It moves the laser up and down to adjust the focus on the left side.

- It moves the working table up and down on the right side.

- The remote control is quite useful.

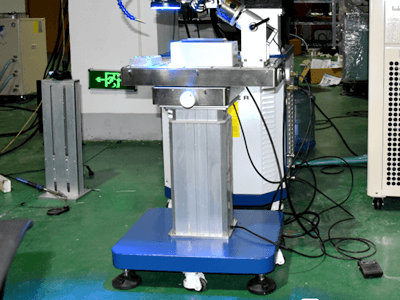

Whole Machine

- This laser welding machine is appropriate for repairing middle and small molds made of stainless steel, carbon steel, iron, etc.

- It is compatible with wire feeders.

Application

A variety of materials, such as cold-working high alloy steel, hot forging high alloy steel, nickel-containing tool steel, high-grade steel, copper alloy, beryllium copper, high toughness aluminum alloy, and other metal materials, can be welded using a mould laser welding machine.

Precision mold repair for digital devices, mobile phones, toys, autos, motorbikes, and other mold production and molding sectors. The original mold can be reused after it has been repaired, which reduces production costs and increases work efficiency. To accelerate the product development process, this technique can also be used to alter the shape or size of the mold.

| Type | BE-W200M | BE-W300M | BE-B400M |

| Three axis table | X=250mm,Y=180mm | ||

| Table capacity | ≤200KG | ≤200KG | ≤200KG |

| Machine battery | 220V±10%/50/60z | 380V±10%/50/60Hz | 380V±10%/50/60Hz |

| Laser type | Nd:YAG pulse xenon lamp | Nd:YAG pulse xenon lamp | Nd:YAG pulse xenon lamp |

| Spot adjusting range | 0.1~3mm | 0.1~3mm | 0.1~3mm |

| Peak wavelength | 1064nm | 1064nm | 1064nm |

| Pulse width | ≤20ms | ≤20ms | ≤20ms |

| Rated output power | 180W | 270W | 360W |

| Maximum laser power | 200W | 300W | 400W |

| Pulse frequency | ≤50Hz | ≤50Hz | ≤50Hz |

| Laser output focal length | 100mm | 100mm | 100mm |

| Laser cooling | Water cooling | Water cooling | Water cooling |

| Monitor | Microscope (rotate360º) | Microscope (rotate360º) | Microscope (rotate360º) |

| Protective gas | 1 (argon) | 1 (argon) | 1 (argon) |

| Cold water capacity | 2700W | 3500W | 5000W |

| Wire diameter | 0.1mm~0.6mm | 0.1mm~0.8mm | 0.1mm~1.0mm |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W300M | 1.45m×0.75m×1.49m,1.6CBM 0.7m×0.6m×1.1m, 0.46CBM 0.7m×0.6m×0.85m, 0.36CBM |

350KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

Jose Duarte

★★★★★Post a review on Aug 21, 2022 From United States

The machine is for ball valve welding and was immediately put into production. The welding scar is minor, and the welding seam is stunning. The fundamental difference is that the distortion is not as severe as in argon arc welding, and the welding seam is smooth and attractive, saving time and effort!

-

Omar MesiaPalacios

★★★★★Post a review on Aug 21, 2022 From Peru

The speed has increased significantly. It used to be difficult to polish the inside corners of argon arc welded joints. Laser welding no longer requires polishing. The speed is quick, no skilled welders are required, and the effect is excellent.

-

Alexandr Perkanuk

★★★★★Post a review on Aug 21, 2022 From Russian Federation

The device is simple to use and capable of continuous operation.

-

Maksim Kandratsyeu

★★★★★Post a review on Aug 21, 2022 From Belarus

The welding equipment has arrived, the logistics are quick, the service is excellent, and I will return if necessary.

-

Mongkon Boonyarakthanya

★★★★★Post a review on Aug 21, 2022 From Thailand

The operation is simplified by the user. The functioning is reliable, and the quality is guaranteed.