Advertising Sign Logo 300W 500W Stainless Steel Laser Welder

| Category | Auto Laser Welding Machine |

| Model No. | BE-W300/BE-W500 |

| Views | 54900 |

| Rating | ★★★★★4.8/5 Based on 400 Votes |

| Price Range | US$3299-US$3699/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 7-15 Days |

| Shipping | Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

A 300W 500W stainless steel laser welder is a powerful and reliable tool for welding stainless steel. It has a wide range of applications, from industrial to medical, that can provide high-quality welds. The laser welder is also more efficient than traditional welding methods, making it an ideal choice for many projects.

Good Features

- It is specifically created for the advertisement letter production sector. This machine employs self-developed adjustable optimization technology, which has the benefits of welding depth, adjustable light spot size, and high strength.

- Independent R&D of high precision control power supply, high anti-interference circuit, touch screen control, user-friendly interface, and easy to learn.

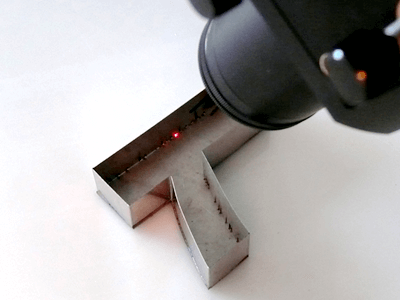

- The Small heat-affected region, no deformation, and no imprint on the reverse side. The welding energy is adjustable, making it appropriate for both deep welding of larger plates and welding of thinner metal plates, potentially lowering the material cost of an advertising sign.

- High-definition CCD monitoring, a liquid crystal display panel, and special placement enable instant identification of the welding component. These features also make it simple to learn, highly efficient, and less likely to cause work-related tiredness than the conventional soldering method.

- The welding connections may be adjusted evenly, making them suited for advertising signs of various sizes and fonts, and the welding efficiency is higher.

- Humanized design: the operation is highly comfortable and reduces tiredness.

- Operating software is simple, easy to use, and powerful.

- The flawless welding surface means that no polishing is necessary, which saves time and effort.

- High efficiency, customized positioning device appropriate for welding of various irregular characteristics.

- Specially developed long focusing lens F=200mm for ultra-high font welding.

- Simple to install, quick and simple to use.

Parts Introduction

LCD Touch Screen Controller

- It uses a built-in controlling system with a touch screen to ensure great sensitivity and easy parameter configuration.

- Depending on the material, users can configure various parameters (current, frequency, pulse, etc.). Parameters can be saved.

LED Luminous Light

- The brightness of the led lights can be adjusted by the operator to ensure eye comfort.

- High brightness, long lifespan, energy savings, and simple installation.

Red Pointer

- Find welding locations quickly, with high precision and faster laser positioning.

- International standard, high heat dissipation, and continuous operation for 24 hours.

CCD Observation System

- It may intuitively reflect welding details that human eyes cannot detect.

- Convenient adjustment for light spot size and solder junction position.

Industrial Water Chiller

- The industrial water chiller can keep the machine cool and in good working order.

- On the chiller panel, operators can change the temperature parameters. The air conditioning system is included with the water chiller.

(300w-1p,400w/500w-2p)

Xenon Lamp

- It uses authentic Xenon lamps from China’s leading brands.

- Lifetime: 8,000,000 times, for example, if you work 8 hours each day, one bulb will last 6-12 months.

- The laser’s power source is a xenon lamp; when it burns out, simply replace it.

Welding Position

- Special fixed focus position rotary bearing positioning rod with anti-friction alloy copper and steel, rapid alignment

Working Table

- Ensure that the glossy sheet is not scratched by using thickened marble or tempered glass.

- Durable and strong body to support the weight of sign letters

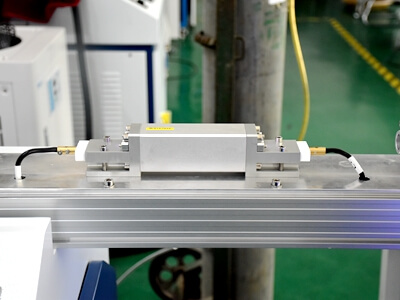

Laser Power Supply

- The capacitor lifetime is extended by using 8 spiral big capacitors and providing a steady current to the xenon lamp.

- Precision control and stable laser output.

- Maintenance-free design and modular construction

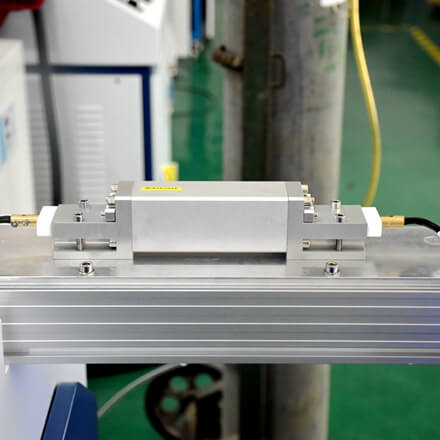

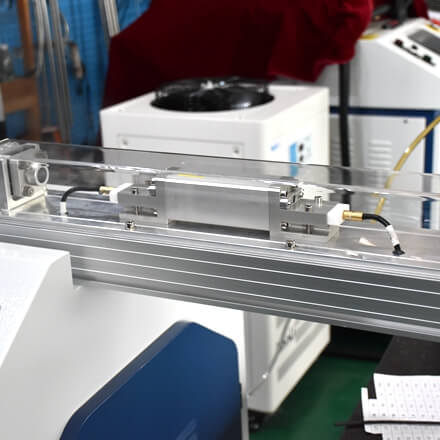

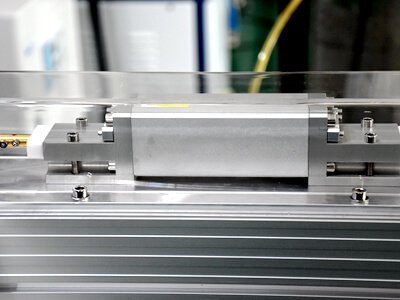

Laser Cavity

- Morgan brand optical cavity imported from the UK, which protects the laser source and extends its longevity.

- Static Free requires the separation of strong and weak currents.

-

Wiring is laid out clearly and follows European standards.

Laser Structure Part

- Dust Cover design prevents dust from entering the lens and reducing power.

Application

Stainless steel laser welding offers a wide range of potential applications for complex manufacturing needs. It is a fast, clean, and precise welding process that can be used for a variety of stainless steel alloys, including the thin and thin-gauge metal components.

The use of stainless steel laser welders in industrial applications can provide many benefits that can help to improve the efficiency and reliability of the welding process. These welders are designed to provide a more precise, consistent weld than other types of welding processes, which can help to reduce the potential for errors and improve the overall quality of the weld

| Model | BE-W300 | BE-W500 |

| Name | 300W Laser welding machine | 500W Laser welding machine |

| Machinery Part | Laser cavity length of 1100 mm, the laser head can rotate 360 degrees. | |

| Working Area | 750*1000MM | |

| Load Bearing | ≤200KG | |

| Machine Power Supply | 220V±10%/50/60Hz | 380V±10%/50/60Hz |

| Laser Type | Nd:YAG impulse xenon lamp | |

| Spot Size | 0.2-3.0mm | |

| Laser Wave Length | 1064nm | |

| Impulse Width | ≤10ms | |

| Laser Power | 300W | 500w |

| Single Pulse Energy | 90J | 120J |

| Impulse Rate | ≤50Hz | ≤100Hz |

| Laser Output Focal Length |

150-250mm Fiber Lead Head 120mm |

150-250mm Fiber Lead Head 120mm |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W300/W500 | 1.9m×0.83m×1.32m, 2.08CBM 0.65m×0.55m×1.08m, 0.39CBM |

370KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

yoon Hong Gun

★★★★★Post a review on Aug 21, 2022 From Republic Of Korea

It’s easy to read on the CCD display. Welding is quite simple, and the process is not challenging. We learned from both the movie and the handbook.

-

Pavel Voronov

★★★★★Post a review on Aug 21, 2022 From Spain

It is more user-friendly. Before purchasing, I was concerned about the business. We are now making good use of it.

-

Jonnathan Quiel

★★★★★Post a review on Aug 21, 2022 From Costa Rica

The advertising sign laser welding equipment is extremely simple to use and run. I’d never used laser welding before. I was surprised at how straightforward it was to learn. The welding effect is effective and precise

-

romel huaraca

★★★★★Post a review on Aug 21, 2022 From Peru

The machine immediately begins production. The welding scar is minor, and the welding seam is stunning. The efficiency has significantly increased.

-

Sal Mey

★★★★★Post a review on Aug 21, 2022 From Cambodia

The laser welding machine weld smooth. We produced beautiful signs.