Double Path Channel Letters Steel Laser Spot Welding Machine

| Category | Auto Laser Welding Machine |

| Model No. | BE-W300II/BE-W500II |

| Views | 48900 |

| Rating | ★★★★★4.6/5 Based on 400 Votes |

| Price Range | US$3500-US$5800/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 7-15 Days |

| Shipping | Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

The metal mould repair laser welding machine is an innovative and revolutionary tool that can help to repair and maintain metal moulds quickly and efficiently. This machine uses a laser beam to heat and fuse metal components together, and can be used to repair complex 3D shapes and structures.

It is capable of repairing complex shapes and components quickly and accurately. With its advanced technology, it is also able to make precise and intricate welds. This makes it a valuable tool for any metal moulding shop, as it can help save time and money.

Good Features

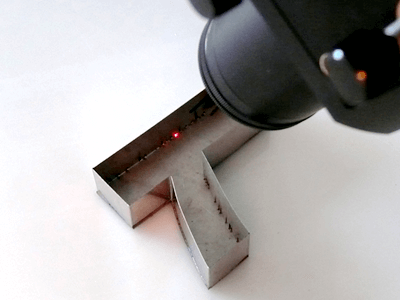

- Double Path Channel Letter made of stainless steel The Laser Welding Machine, with a 5m fiber laser cable, is ideal for welding large lettering and intricate metal sheet welding.

- The red light quickly locates the welding point, the CCD provides easy inspection, and an optional microscope is available

- To prevent the shiny front plate from being scratched, use a marble work surface

- High-speed machining, fixed-focus rotation of the bearing rod without the need for a CCD or microscope. It may rapidly focus on welding.

- Small thermal deformation and heat impacted zone

- On the metal word, local heat treatment may be applied

- Available for the processing of complicated shapes of pieces and short words.

- Processing without creating noise or polluting the environment.

- Friction plate welding, ultra fine bearing rotating positioning rod, and no need to change the spot position in the corner of the font.

- The quality of the current metal character has been substantially improved as a result of the sophisticated processing approach.

- A customized LED ring lamp with no dead spots

- The self-produced high peak laser power supply is difficult to weld aluminum for other brands. The device is simple to use and may (500W models for welding aluminum models).

Parts Introduction

Handheld Fiber Laser Gun

- To support various welding needs, a handheld portable 5m fiber cable with a Mitsubishi optical core imported from Japan is used.

- Excellent heat dissipation, long lifespan, and low laser usage.

LCD Touch Screen Controller

- It uses an integrated control system with a touch screen, ensuring great sensitivity and facilitating simple parameter configuration.

- Users can configure many settings (current, frequency, pulse, etc.) based on the material. Parameters can be saved.

LED Luminous Light

- The brightness of the led lights can be adjusted by the operator to ensure eye comfort.

- High luminance, a long lifespan, energy efficiency, and simple installation

Red Pointer

- Find welding locations quickly, with high precision and faster laser positioning.

- International quality and excellent heat dissipation, with a working time of 24 hours.

CCD Observation System

- It can instinctively reflect welding subtleties that human eyes cannot discover.

- Convenient adjustment for light spot size and solder junction position.

Industrial Water Chiller

- An industrial water chiller can keep the machine cool and in good working order.

- The chiller panel’s temperature parameters can be changed by operators. The air conditioner system is included with the water chiller.

(300w-1p,400w/500w-2p)

Xenon Lamp

- Original Xenon lamps from China’s leading brands are used.

- Lifetime: 8,000,000 times, for instance, if a lamp is used for 8 hours every day, it can last 6 to 12 months.

- The laser’s power source is a xenon lamp; when it burns out, simply replace it.

Welding Position

- Special fixed focus position rotary bearing positioning rod with anti-friction alloy copper and steel, rapid alignment

Working Table

- To prevent the glossy sheet from being damaged, make sure the material is thick marble or tempered glass.

- Durable and strong body to support the hefty weight of sign letters

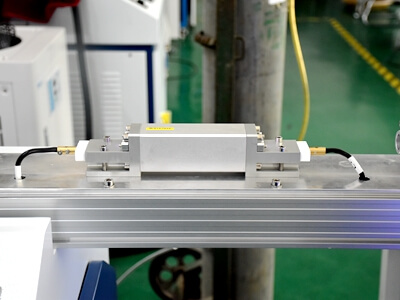

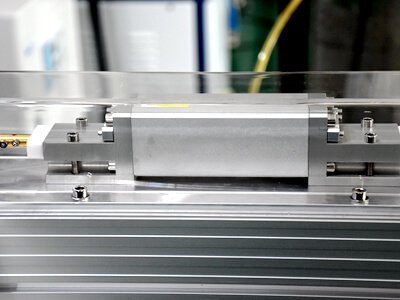

Laser Power Supply

- Utilizing eight spiral-shaped big capacitors and providing xenon lamps with consistent current increases capacitor lifetime.

- Consistent laser output and accurate control.

- Maintenance-free design and modularity

Laser Cavity

- Morgan brand optical cavity imported from the United Kingdom, which protects the laser source and increases its lifespan.

- For static-free operation, strong current and weak current separate.

- Wiring is clearly laid out and adheres to European standards.

Laser Structure Part

- Dust Cover design prevents dust from entering the lens and reducing power.

Application

The stainless steel letter welding machine is used to make stainless steel letters, LED luminous characters, AD Logos, signs, metal letters, LED lighted letters, bespoke metal signage, outside billboards, and other fast welding.

Welding Equipment:

0.1-2 mm thick galvanized, bronzing, and stainless steel; 2 mm copper and aluminum (500w laser welder). A handheld laser welding machine, portable laser welding machine, advertising letter welding machine, laser welder for sale, and laser welder for sale are all names for a channel letter welding machine.

| Model | BE-W300II | BE-W500II |

| Name | 300W Laser welding machine with handheld laser pen | 500W Laser welding machine with handheld laser pen |

| Machinery Part | Laser cavity length of 1100 mm, the laser head can rotate 360 degrees. | |

| Working Area | 750*1000MM | |

| Load Bearing | ≤200KG | |

| Machine Power Supply | 220V±10%/50/60Hz | 380V±10%/50/60Hz |

| Laser Type | Nd:YAG impulse xenon lamp | |

| Spot Size | 0.2-3.0mm | |

| Laser Wave Length | 1064nm | |

| Impulse Width | ≤10ms | |

| Laser Power | 300W | 500w |

| Single Pulse Energy | 90J | 120J |

| Impulse Rate | ≤50Hz | ≤100Hz |

| Laser Output Focal Length |

150-250mm Fiber Lead Head 120mm |

150-250mm Fiber Lead Head 120mm |

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-W300II/BE-W500II | 1.9m×0.83m×1.32m, 2.08CBM 0.65m×0.55m×1.08m, 0.39CBM |

370KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

yoon Hong Gun

★★★★★Post a review on Aug 21, 2022 From Republic Of Korea

It’s easy to read on the CCD display. It is quite simple to weld, and the operation is simple. We learned from the film and the instruction booklet.

-

Pavel Voronov

★★★★★Post a review on Aug 21, 2022 From Spain

It is more user-friendly. Before I purchased, I was concerned about the operation. We are now making good use of it.

-

Jonnathan Quiel

★★★★★Post a review on Aug 21, 2022 From Costa Rica

The advertising sign laser welding equipment is simple to use and run. I’ve never used laser welding before. I wasn’t expecting it to be so basic and straightforward. The welding effect is effective and precise.

-

romel huaraca

★★★★★Post a review on Aug 21, 2022 From Peru

The machine immediately begins production. The welding scar is barely visible, and the welding seam is stunning. The efficiency has significantly increased.

-

Sal Mey

★★★★★Post a review on Aug 21, 2022 From Cambodia

The laser welding machine produces a flawless weld. We made some lovely signs.