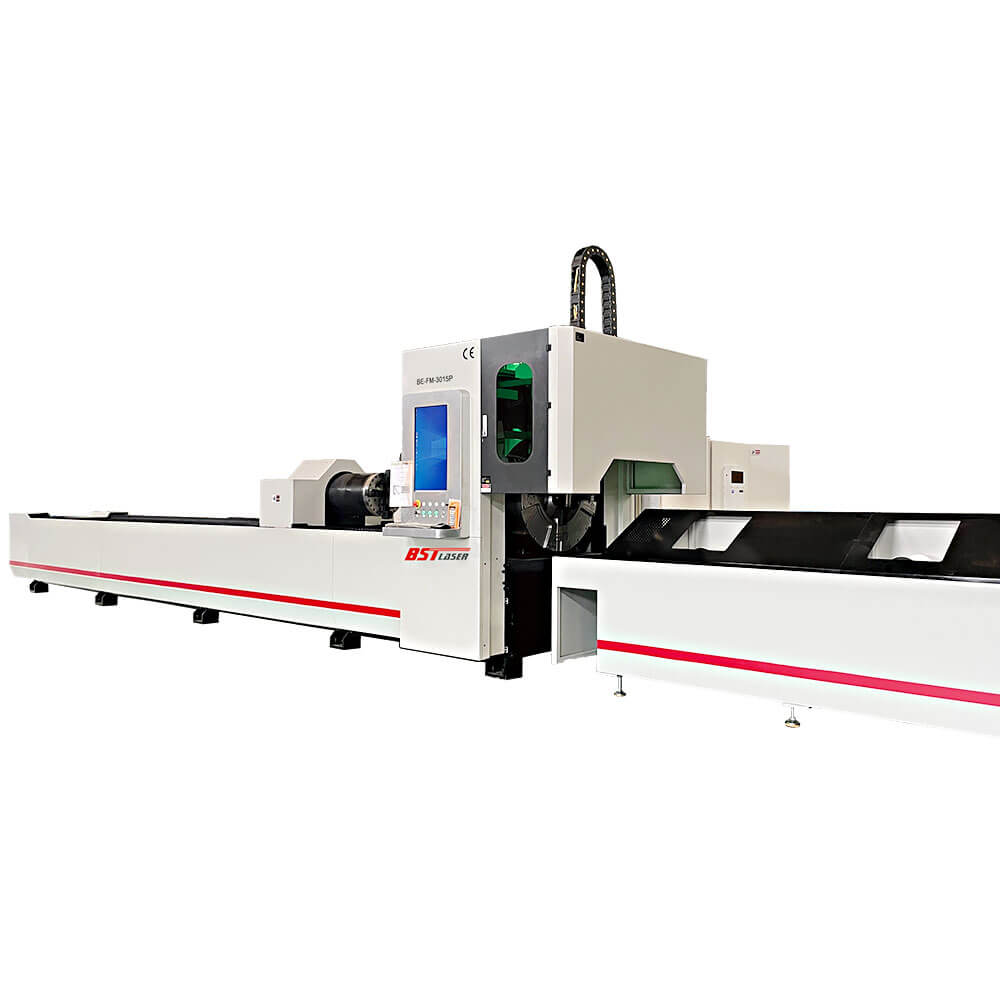

Stainless Steel Fiber Metal Square Tube Laser Cutting Machine

| Category: | Fiber Metal Laser Cutting Machine |

| Model No.: | BE-FM-6022P |

| Views: | 4800 |

| Rating: | ★★★★★5/5 Based on 5200 Votes |

| Price Range: | US$25,000 – US$70,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer |

| Leading Time: | 40-60 Days |

| Shipping: | Sea Shipment |

| Warranty Period: | 36 Months for Machine and 24 Months for Fiber Laser Device with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

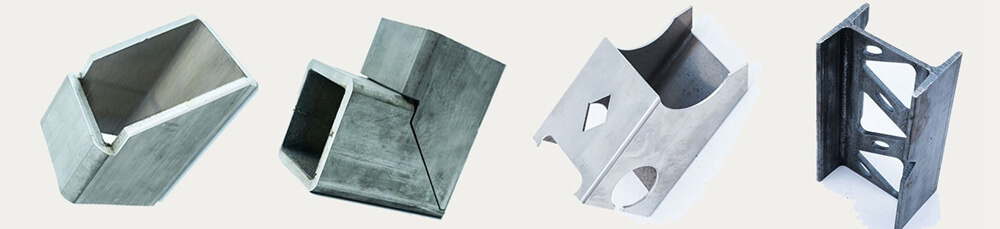

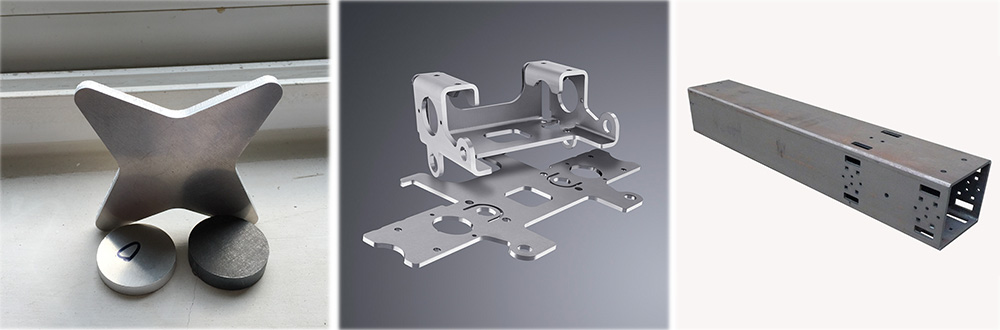

Pipes and profiles are widely utilized in a variety of applications ranging from mechanical engineering and system construction to the furniture industry. Tube and fiber laser cutting technology enables the automatic manufacturing of CAD-designed parts with precision and repeatability. It is a high-precision metal processing machine used to cut various tubes and pipes such as round, square, rectangular, channel, angle, and special-shaped tubes.

STANDARD COMPONENTS

◆CYPCUT®FSCUT3000S CNC Control System

◆RAYTOOLS®Intelligent 3D Dimension Tube Laser Cutting Head

◆Fuji®High Dynamic EtherCAT servo drive

◆BSTLASER®Dynamic System 4.0: 1.5g Acceleration

◆BSTLASER®Fast Piercing 2.0: Ultra Preformation

◆Smoke Extraction Fan System

◆Fiber Laser Source: Raycus/IPG/MAX/JPT

◆Class IV safety system and CE marking

◆CYPCUT®Embedded Pcs: Industrial PCs with directly integrated I/O level

◆Hiwin®High performance and high accuracy rack and pinion system

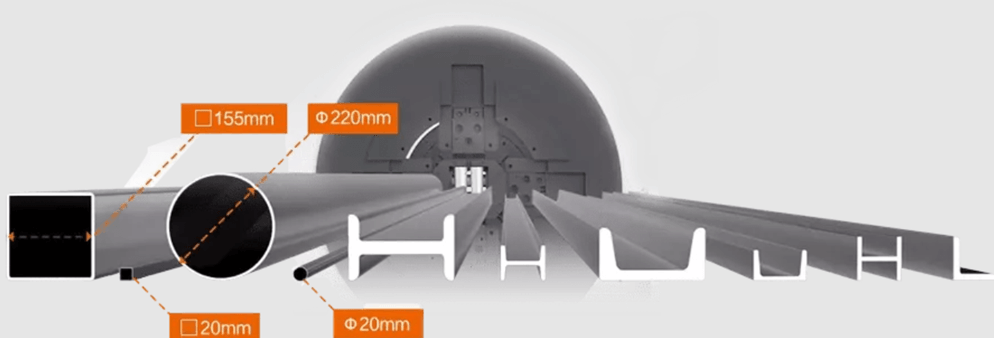

◆Tube Diameter: Φ220 (Optional: Φ160/Φ230/Φ350)

◆Automatic Tube Length: 6 Meters (Optional: 8m,12m,16m, etc )

Metal Cutting Capacity

| Laser Power | 2000W | 3000W | 4000W | 6000W | |

| Nominal power | kw | 2 | 3 | 4 | 6 |

| Power requirement | kw | 7 | 10 | 13 | 19 |

| Wavelength | nm | 1074 | 1074 | 1074 | 1074 |

| Cutting capacity | |||||

| Carbon steel | mm | 20 | 22 | 25 | 25 |

| Stainless steel | mm | 8 | 10 | 12 | 20 |

| Aluminum Alloys | mm | 6 | 8 | 10 | 16 |

| Brass | mm | 5 | 6 | 8 | 12 |

Machine Feature:

- Optional three-chuck construction, double cutting position, and laser tube cutting procedure to achieve “zero” tail material.

- Making use of a pneumatic four-claw, self-centering, bus-mastering chuck with multi-functional claws that can grip pipes of different cross-sections.

- With the help of specialized pipe-cutting programming software, channel, angle, and H-shaped steels as well as custom-shaped pipes may be cut, helping to reduce waste and increase cutting efficiency;

- The sharp and thin cutting nozzle portion can successfully avoid the special-shaped section by using a capacitive three-dimensional fiber laser cutting head with high sensing accuracy, high sensitive response, and the most reliable performance.

- Use an innovative servo auxiliary support device to provide accurate processing, effective support, and to stop the pipe from sagging.

- A built-in full parameter library for the cutting process that has an intuitive parameter interface enables “one-click setting” processing technology based on pipe types, which improves processing intelligence and effectiveness.

- With the ability to manage the cutting of sharp corners, seamed edges, and other cutting processes, smooth cutting quality and high efficiency on the profile section are guaranteed.

Parts Introduction

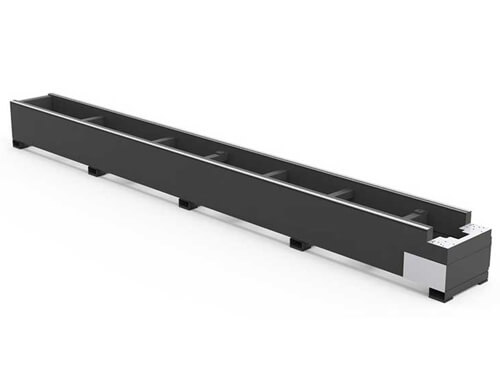

Heavy Loading Machine Body

- Adopting heavy-duty steel plate welding construction, processed by large gantry CNC lathe processing, twice annealing.

- The machine body can assure stability and non-deformation for 50 years, and has the features of stable structure, good rigidity, and high dynamic response, integrated cast-aluminum gantry provides high speed and high balancing performance.

Auto Focus 3D Laser Cutting Head

- Intelligent CNC laser cutting head with automatic focusing and fast dynamic reaction. Using a three-dimensional capacitive fiber laser cutting head with high sensing accuracy and sensitive response, as well as the most stable and dependable performance.

- The sharp laser cutting tip effectively avoids the special-shaped part.

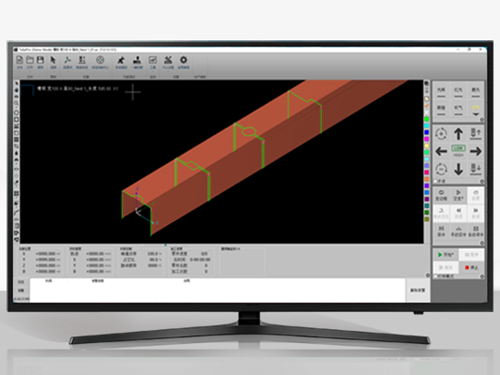

FSCUT3000S Cypcut Control System

- FSCUT3000S is developed for professional tube cutting, providing high accuracy and efficiency production of conventional tubes (rectangle, circle, oval, elliptical, and obround, among others) and steel channels (T/U/H shaped).

- TubePro tube cutting software and CypCut sheet cutting software are used.

- 32-bit PCI bus, 132MB/S interface.

- Motor control: X/Y1/Y2/W axis pulse output with a maximum frequency of 3MHz.

- Access encoder feedback on the X/Y1/Y2 axes, with a maximum sampling frequency of 10MHz.

- W axis port can be allocated to a rotating axis or autofocus unit.

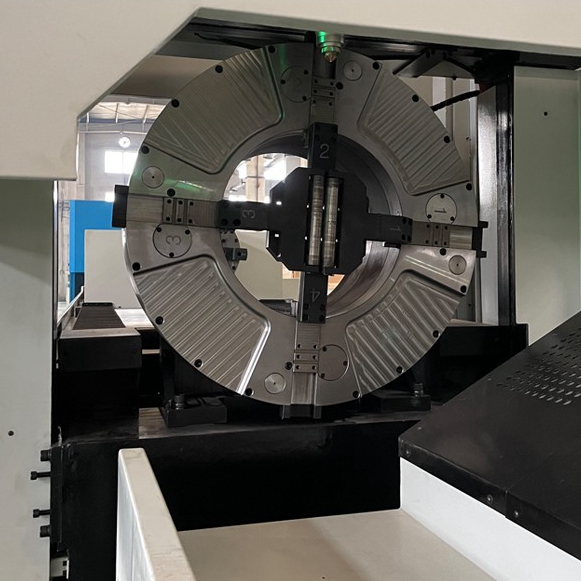

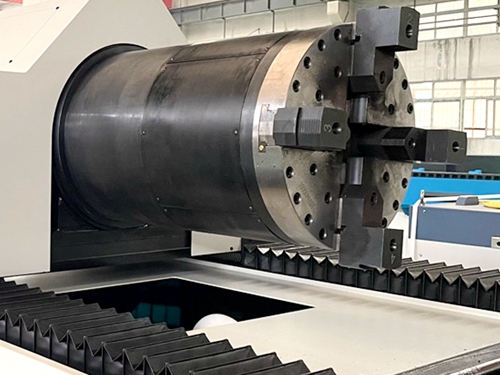

Pneumatic Double Action Chuck

- Specially developed for laser pipe and sheet cutting equipment. The device can be utilized as an independent spinning spindle, clamping and loosening swiftly through the side rotating air intake, and the air supply can be unplugged before working.

- It has an innovative chuck clamping technology, can automatically adjust the center of gravity, and the clamping power is automatically adjusted to avoid thin tube clamping damage.

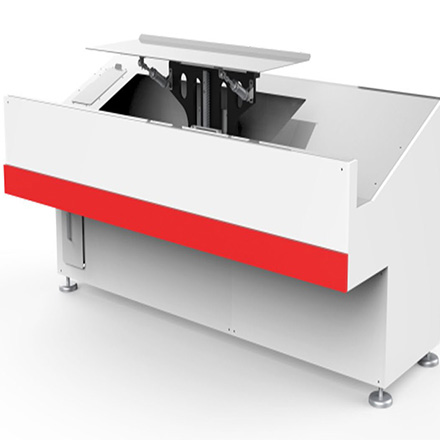

Automatic Front Picking Device

- To realize intelligent processing and boost the output value of pipe cutting, a friendly front materials collection device is used, and the cut waste is automatically dropped to the waste cart.

Automatic Diameter Adaptment Wheel

- It uses an innovative tube support design to overcome deformation issues throughout the long tube-cutting process.

- Inside, a robust design ensures excellent stiffness and strength.

Japan Servo Motors

Imported with a high-power servo system, it is possible to achieve exceptionally precise positioning because of its superior dynamic response acceleration property and closed-loop control method, which allows the moving positioning mechanism to work smoothly, reliably, and without maintenance.

Application

Laser-based cutting and welding technology is becoming more common in a wide range of industrial applications. Laser cutting is a non-contact technology that can create complicated shapes with excellent accuracy and quality.

Metal cutting fields include machinery components, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automobile parts, and others.

Application Materials

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheets, metal plate, metal pipe and tube, etc. Fiber Laser Cutting Machine.

Optional Items

| Model | BE-FM-6016P | BE-FM-6022P | BE-FM-6035P |

| Tube Range Size |

Round: Φ15-Φ155mm Square: □16-□155mm Rectangular: Long Side≤155mm |

Round: Φ15-Φ220mm Square: □20-□220m Rectangular: Long Side≤220mm |

Round: Φ15-Φ345mm Square: □20 – □240mm Rectangular: Circumcircle Φ≤345mm |

| Length Range | 0-6000mm | 0-6000mm | 0-6000mm |

| Laser Power | 2000W 3000W 4000W 6000W | ||

| Laser Source | Raycus (Optional: Max/JPT/IPG) | ||

| Maximum Load Of Chuck | 400kg(65kg/m) | ||

| Chuck Speed | 85rpm | ||

| Max. Running Speed | 100m/min | ||

| Tailing Length | 0-180mm | ||

| Laser wavelength | 1070nm-1080nm | ||

| Minimum line width | ≤0.1mm | ||

| X/Y Location Accuracy | 0.03mm | ||

| Re-location precision | ±0.02mm | ||

| Max Acceleration | 1.5G | ||

| Supporting Format | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc | ||

| Power demand | 3 PHASE AC 380V 50HZ/60HZ | ||

| Cooling Way | Water Cooling | ||

| Table-driven system | Japanese Imported Servo Motor & Driving System | ||

| Focus Method | Following and Automatic Adjust Focus | ||

| Working Environment Temperature | 0℃~45℃ | ||

| Working Environment Humidity | 5%~95% non-condensing | ||

| Dimension | 11800×3500×2200 | ||

Package and Shipment

|

|

| Moisture Proof sealed vacuum packaging which Comply with Sea-Worthy Standard | Fixed well and load in the container 40’GP EXW, Ship to Sea Port |

-

Marco Vergara

★★★★★Post a review on Aug 21, 2022 From Mexico

Good company, speedy, and really good service. As usual, a fantastic product.

-

Sanja

★★★★★Post a review on Aug 21, 2022 From Serbia

I’m really pleased with ov laser; this is the tenth machine I’ve ordered from them.

-

Philip Im

★★★★★Post a review on Aug 21, 2022 From Korea

At first sight, I fell in love with it; it has a very attractive yet sturdy design, and the cutting precision is considerably higher than the large size 3015 that I previously purchased. I adore it.

-

Vardan Avetisyan

★★★★★Post a review on Aug 21, 2022 From Armenia

Very powerful, I can use the machine to cut metal plate sheets and various tubes, the price is higher but well worth it, and I strongly recommend it to clients.

-

Salvatore marrapesa

★★★★★Post a review on Aug 21, 2022 From Italy

All issues have been resolved; we may require some technical assistance during testing, but everything is now operational and the cutting is excellent.

-

Hashrat Ali

★★★★★Post a review on Aug 21, 2022 From UAE

We can build and test the machine using your user manual and training video; no technical assistance is required; please check the cutting sheets by myself.

-

Miguel A Hernandez

★★★★★Post a review on Aug 21, 2022 From USA

Good company, quick and efficient service. As usual, a fantastic product.