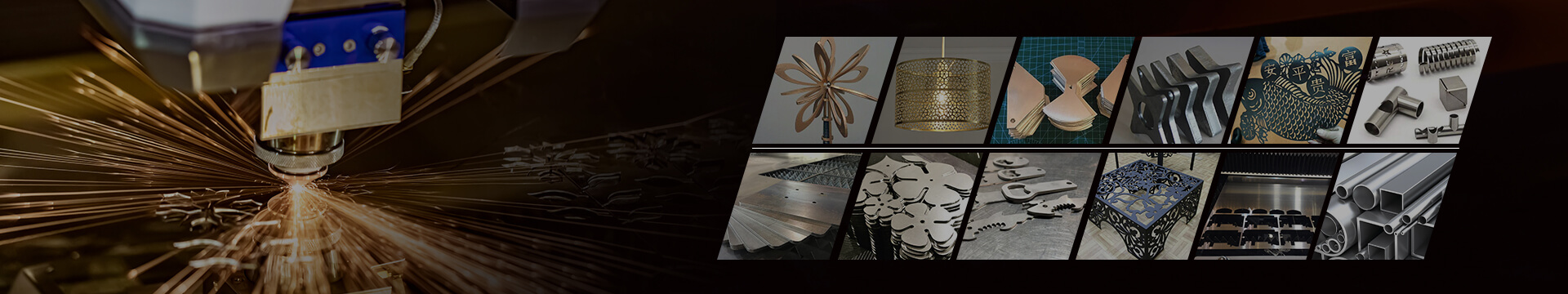

Dual Use Flat Sheet and Pipe Metal Fiber Laser Cutter

| Category: | Fiber Metal Laser Cutting Machine |

| Model No.: | BE-FM-3015GP |

| Views: | 3800 |

| Rating: | ★★★★★5/5 Based on 5200 Votes |

| Price Range: | US$15,000 – US$45,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer |

| Leading Time: | 40-60 Days |

| Shipping: | Sea Shipment |

| Warranty Period: | 36 Months for Machine and 24 Months for Fiber Laser Device with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

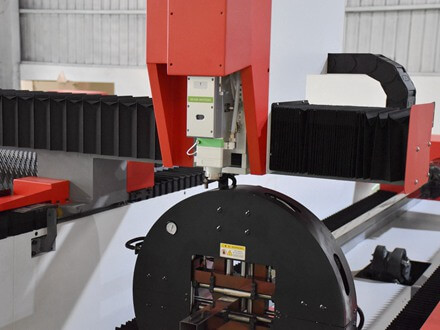

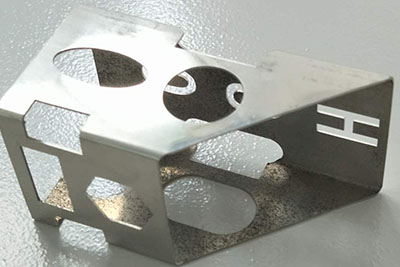

It’s an upgraded model for both cutting sheet and tube,rich in equipment functions. Solve the cutting scheme of many kinds of workpiece,Safe and reliable switching sheet and tube cutting function.It adopts an electric clamp design on both sides and it can modulate the center automatically,the diagonal adjustable range is 20-240mm. (other size can be customized )

STANDARD COMPONENTS

◆ CYPCUT®FSCUT3000S CNC Control System

◆ Yaskawa®High Dynamic EtherCAT servo drive

◆ BSTLASER®Dynamic System 4.0:1.5G Acceleration

◆ BSTLASER®Fast Piercing 2.0:Ultra Performation

◆ Automatic Table Exchanger 3015 (Optional 4015,4020,6015,6020)

◆ Smoke Extraction Fan System

◆ Fiber Laser Source Raycus 2000w 3000w 4000w 6000w

◆ Class IV safety system and CE marking

◆ CYPCUT®Embedded Pcs: Industrial PCs with directly integrated I/O level

◆ Hiwin®high performance and high accuracy rack and pinion system

◆ BSTLASER®Φ130/Φ170/Φ240/Φ360

◆ BSTLASER®3 meters / 6 meters/12 meters

Metal Cutting Capacity

| Laser Power | 2000W | 3000W | 4000W | 6000w | |

| Nominal power | kw | 2 | 3 | 4 | 6 |

| Power requirement | kw | 7 | 10 | 13 | 19 |

| Wavelength | nm | 1074 | 1074 | 1074 | 1074 |

| Carbon steel | mm | 20 | 22 | 25 | 25 |

| Stainless steel | mm | 8 | 10 | 12 | 20 |

| Aluminum Alloys | mm | 6 | 8 | 10 | 16 |

| Brass | mm | 5 | 6 | 8 | 12 |

Machine Feature:

- All accessories are of the highest caliber in the laser machine business, with an industrial-grade machine bed design. Every accessory is real, and if found to be false, it can be returned.

- Use a gantry-type mid-drive structure, a rack double-servo drive structure, and a high torque. Yaskawa servo motor from Japan. The highest acceleration can reach 1.5G thanks to the Taiwan precision rack and high precision reducer. Assure high-speed, precise operation.

- The machine bed has a cast aluminum gantry integrated into a heavy-duty plate sheet welded structure. Large gantry CNC lathe processing with twice annealing significantly eliminates tension.

- High-performance fiber laser and precise cutting head.

- Control system for high-performance laser cutting that is totally closed-loop.

- Precision industrial linear module system with Z-axis

- Yichu brand drag chain cable, as well as a dependent control cabinet and an industrial standard foot tol.

- Schneider Electric components, European electrical standard design.

Parts Introduction

Machine Body

- Adopting a heavy-duty steel plate welding structure, large gantry CNC lathe processing, twice annealing, CNC machining, and three times milling.

- The roughing and leveling pass is the first, the fine milling pass is the second, and the final milling pass is the third.

- The machine body has a robust structure, good rigidity, and strong dynamic responsiveness, and can guarantee stability and non-deformation for 50 years.

- The integrated cast aluminum gantry ensures great speed and stability.

Sheet Metal Cutting Bed

- Heavy duty cutting bed, durable usage, eliminate the stress effect without deformation.

- Machine bed stable performance ensures laser head move precisely on XY axis and high accuracy cutting.

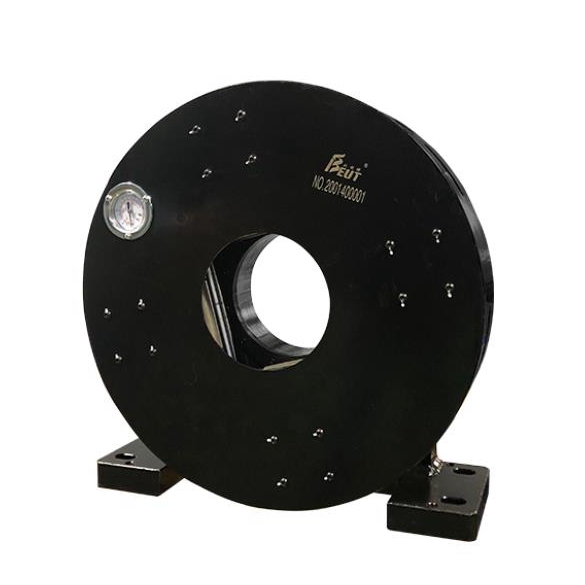

Pipe Tube Rotary System

- Can be adjusted automatically based on pipe and square size

- Available Size :⌀130 ⌀170 ⌀240 and ⌀360 (other special size can be customized )

Fiber Laser Source

- China top brand Raycus/Max fiber laser source

- Single module fiber laser source with good quality laser beam<1.2

- High efficient photoelectric conversion>40%

- High quality stable laser beam, and powerful capacity resist to high sensative materials

Cast Aluminum Beam

- The welding gantry’s high rigidity and strength assure high speed and high balance performance, with low weight, good dynamic response, faster acceleration, and a better overall cutting impact.

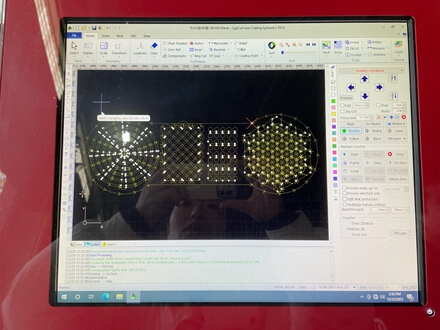

FSCUT3000S Cypcut Control System

- FSCUT3000S is intended for professional tube cutting, supporting standard tube (rectangle, circle, oval, elliptical and obround, etc.), and steel channels (T/U/H shaped) manufacturing with high precision and efficiency.

Simple Pneumatic Double Action Chuck

- It is intended for laser pipe and sheet cutting equipment. The device can be utilized as an independent spinning spindle, clamping and loosening swiftly via the side rotating air intake, and the air source can be unplugged before working.

- After the workpiece base is secured, all that remains is to attach the corresponding motor and gear connection, as well as connect the compressed air source (0.25-0.9Mpa) to clamp the workpiece and cause it to spin. Mostly used for clamping and rotating workpieces.

Back Chuck

- High stability

Integral support structure improves support and load-bearing stability - Less material left

New extended barrel design, extremely material-saving - Easy to apply

Standard reducer base, simple structure, flexible options - Special-shaped pipe clamping

Optional clamping of various profiles to keep pipe fittings from slipping

Diameter-Variable Wheel

- The diameter-variable wheel has a scale and adopts the cable-stayed type design, no need to punch hole in the ground.

- Durable and wear resist

Transmission System

- Germany Roust grinding grade rack& high precision linear square track (Original Genuine)

- It ensures high cutting speed with extremely precision position and long service life.

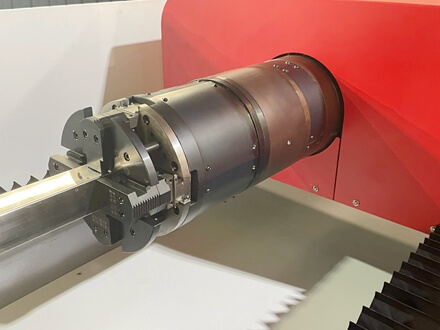

Auto Focusing Laser Cutting Head Raytools

- Simple to maintain modular design.

- To reduce human intervention and improve piercing and cutting efficiency, use autofocus.

- 3 Cover glasses (top, middle, and bottom) to protect collimation & focus lens.

- Dustproof to IP65, patented cover glass cover plate.

- Dust prevention on all fronts.

- QBH, QD, G5 Fiber Interface

- 170mm/s is the speed.

- Precision: 50um.

- Collimation Side (Top)Φ24.9*1.5mm.

- 27.9*4.1mm focusing side (bottom/middle).

- Assistant Gas: ≤30bar.

- 5.7kg in weight.

Japan Servo Motors

- AC Servo Motor with Driver-7 series from Japan.

- The ability to achieve extremely precise positioning with an imported servo system is ensured by its excellent dynamic response acceleration characteristic and closed-loop, control approach, which allows moving positioning mechanisms to run smoothly, dependably, and without the need for maintenance.

Electric Cabinet

- Comply with European CE quality standard and can bear heavy working load and outer environment affect

- Reliable clear wiring ensures safety and easy maintenance

- Strong and weak current are separated

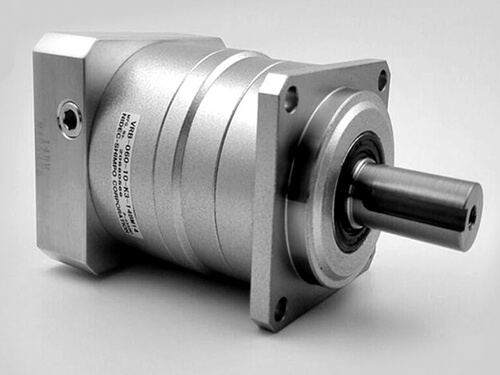

Reducer

- Flange output

- Japan Shimbo reducer.

- Accuracy and stability life is greater than ten times that of the shaft output

- Grade 3 accuracy

Auto Oiling

- Provide automatic lubrication to machine parts

- Easy for daily maintenance

- Intelligent management and ncrease the efficiency

PC Control

- Integrated Cabinet with industrial PC system and well adjusted software for direct usage

- With advance design LCD touch screen control and it can be rotated in 360 degree

- Small and compact, save space and shipping freight

BCS Auto Height Adjustment

- High precision, fast following response, high sensitivity, with advanced functions such as off-board following, safety and anti-collision

Cooling System

- Hanli top China brand with a variety of alarm protection functions.

- It operates in two modes: constant temperature and intelligent temperature management.

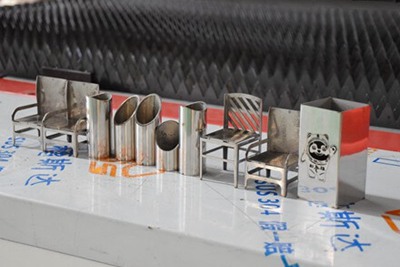

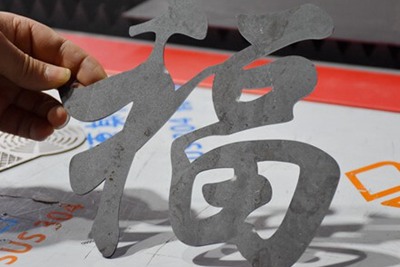

Application

Applicable Industries

Metal cutting fields include machinery components, electrics, sheet metal fabrication, electrical cabinets, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automobile parts, and others.

Materials for Use

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass, and other metal sheets, plate, pipe, and tube, and so on. Laser Cutting Fiber Machine

|

|

|

|

|

|

|

|

Optional Items

| Model | BE-FM-3015GP | BE-FM-4020GP | BE-FM-6020GP |

| Working Size | 3000×1500mm | 4000×2000mm | 6000×2000mm |

| Laser Power | 1500w 2000w 3000W 6000W | ||

| Laser Source | Raycus (Optional: Max/Reci/IPG) | ||

| Laser Technology | Germany Technology | ||

| Optional Size | 4000×1500mm/6000×1500mm/6000×2000mm | ||

| Max. Cutting Speed | 30-50 Meters / Min (up to materials) | ||

| Max. Location speed | 60m/min | ||

| Laser wavelength | 1070nm | ||

| Minimum line width | ≤0.1mm | ||

| X/Y Location Accuracy | 0.03mm | ||

| Re-location precision | ±0.02mm | ||

| Max Acceleration | 1.5G | ||

| Max. moving speed | 100m/min | ||

| Supporting Format | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc | ||

| Power demand | 3 PHASE AC 380V 50HZ/60HZ | ||

| Cooling Way | Water Cooling | ||

| Worktable max. load | 6000KGS | ||

| Transmission Method | gantry type double rack servo drive | ||

| Table-driven system | Japanese Imported Servo Motor & Driving System | ||

| Focus Method | Following and Automatic Adjust Focus | ||

| Control software | Cypcut | ||

| Working Environment Temperature | 0℃~45℃ | ||

| Working Environment Humidity | 5%~95% non-condensing | ||

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-FM-3015GP | 4191mm×2520mm×1326mm, 14CBM | 6000KG |

|

|

|

| Inside layer is covered by thickening plastic bag and foam for waterproof. | Loading container EXW factory, workers putting machine into container | Send to the named sea port and load in the container |

-

Philip Im

★★★★★Post a review on Aug 21, 2022 From Korea

At first sight, I fell in love with it; it has a very attractive yet sturdy design, and the cutting precision is much higher than the big size 3015 that I previously purchased; I adore it.

-

Vardan Avetisyan

★★★★★Post a review on From Armenia

Very Power, I can use the machine to cut metal plate sheets and other tubes, while the price is higher but truly deserved, strongly recommend to clients.

-

Salvatore marrapesa

★★★★★Post a review on Aug 21, 2022 From Italy

All issues have been resolved; we may require some technical assistance during testing, but everything is now operational and the cutting is excellent.

-

UAE

★★★★★Post a review on Aug 21, 2022 From Hadhrat Ali

Using your instruction manual and training video, we can assemble and test the machine without the need for technical assistance; I’ll examine the cutting sheets.

-

Miguel A Hernandez

★★★★★Post a review on Aug 21, 2022 From USA

Fast, efficient, and excellent service from the company. As usual, a fantastic product.

-

Jose Eduardo Paris Muñoz

★★★★★Post a review on Aug 21, 2022 From Brazil

The technical help is excellent and the work is consistently superb with lots of instructions. I’m really pleased with ov laser; this is my eighth machine from them.