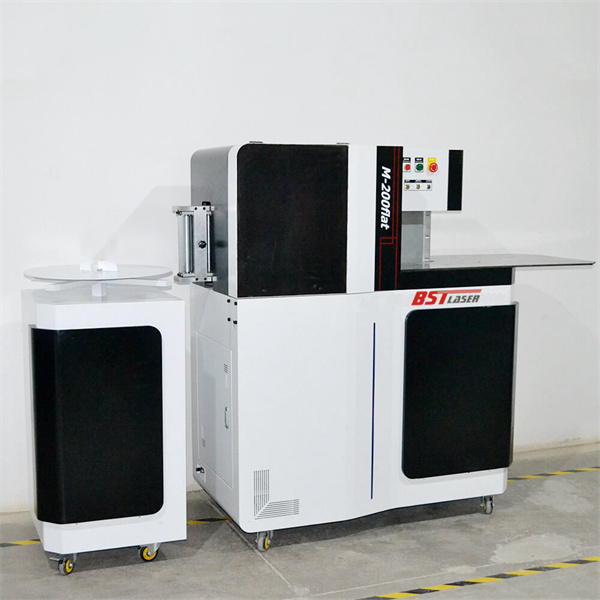

Landscape Stainless Steel 3D Channel Letter Making Machine

| Category: | Channel Letter Bending Machine |

| Model No.: | BEL-M200 |

| Views: | 5500 |

| Rating: | ★★★★★4.9/5 Based on 1200 Votes |

| Price Range: | US$4000 – US$6500/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time: | 10-15 Days |

| Shipping: | Sea/Train/Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

A stainless steel channel letter making machine is an essential tool for any business that produces custom signage. This type of machine offers a wide range of capabilities, from cutting and forming letters to welding and finishing them off. Using a stainless steel channel letter-making machine can be beneficial for many businesses as it offers some advantages. These include a high-quality finish, a faster production process, and low maintenance costs. Additionally, it can be used for a variety of applications, including creating signs, logos, and more.

Machine Feature:

- Independent feeding cabinet with multiple letter sizes

- Machine covers use a high-end chrome plating method that is more wear-resistant and corrosion-resistant, extending the machine’s life.

- Servo control combined with a ball screw transmission that has a high degree of precision and a rapid feeding rate

- Servo-controlled dual-axis alternating telescopic arc-bending structure with high arc bending strength and degree of arc formation

- With a one-of-a-kind material reminder mechanism to ensure that no material is wasted due to cutting

- Electrical portion modularized, separated strong and weak circuitry sections, no interference, more stable

Parts Introduction

Strong Machine Design

- Strong machine body with European Standard Design that ensures excellent stability and 50 years of deformation-free operation.

Enlarged Bending Height: 20-200mm

- Extensive Bending Height:20-200mm

- Ideal for creating landscape letters, bevel letters, and outdoor large letters.

- Eliminate common feeding slip issues and achieve excellent feeding precision.

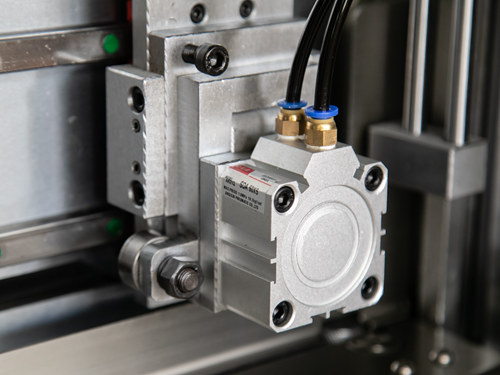

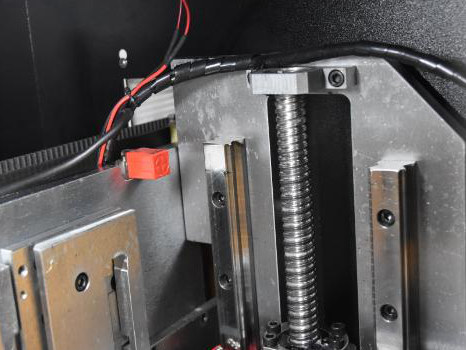

Ball Screw Transmission Structure

- TBI Ball Screw Transmission Provides Maximum Precision and Accuracy

- High torque produces a finished letter with a high forming degree, eliminating the need for manual after-treatment.

Unique Material Receiving Reminder Function

- It ensures that processed materials are not wasted, that aluminum coils and stainless steel materials are used more sensibly and effectively, and that expenses are saved.

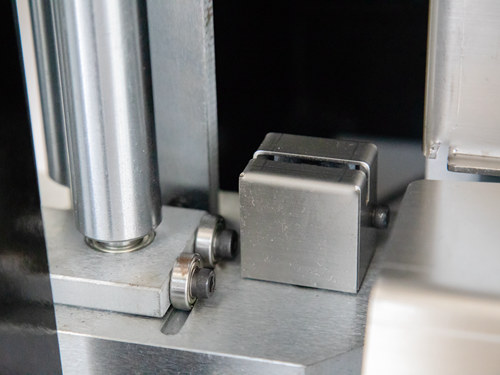

Alternating Telescopic Arc-bending

- With a high bending torque, finished letters with narrow angles and complicated images are produced.

Enlarged Servo Motor

- Fast response in tens of milliseconds, stable operation

- Large torque, excellent precision, and rapid feeding

German Imported Carbide Knife

- Double-sided with 8 flutes, saves time and does not require sharpening

- It is simple to cut hard stiffness materials and bend 1.5mm stainless steel.

Application

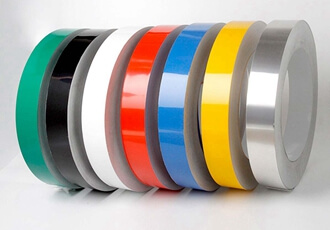

The stainless steel channel letter making machine is a new type of production machine used in the manufacturing of stainless steel channel letters. It is designed to provide high-quality and consistent production of stainless steel channel letters with a shorter production time. Aluminum strip, stainless steel, galvanized sheet, iron, and other flat metal materials can be used.

Industry applications include logos, steel letters for cars, brushed steel letters, neon signs, stainless steel letters for homes, light box manufacture, and metal outdoor letters and numbers. M200 is designed specifically for outdoor landscape stainless steel letters and clients who place a high value on bending quality and efficiency.

Optional Items

| Category | Feeding system | Precision screw transmission and mechanical arm alternatively feeding structure (Closed loop self-test system) |

| Slotting system | Hard Alloy Planer | |

| Bending system | Double Axis Telescopic Bending system | |

| Driving motor | Servo motor 3 set; stepper motor 1 set | |

| Weight | 480kg | |

| Dimensions | Body: L2300mm×W770mm×H1570mm; Feeding table: L500mm×W550mm×H1200mm | |

Performance |

Material category | stainless steel, galvanized sheet, flat aluminum (20—200mm) |

| Material thickness | Stainless steel 0.3—1.2mm Galvanized sheet 0.4—1.2mm Flat aluminum 0.6—1.5mm |

|

| Support format | AI PLT DXF NC | |

| Feeding accuracy | Length±0.1mm; Radius>4mm | |

Sfotware |

Control card | Leetro Four-axis motion control card |

| Software system | Autodrive bending system | |

| Input voltage | 220V 50Hz 3Kw | |

| Air pressure | 0.6-0.8Mpa |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-M200 | 210cm×81cm×180cm, 3.062CBM | 450KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craft case. |

-

Hossein Azimi

★★★★★Post a review on Aug 21, 2022 From UK

The machine is very strongly mechanically and features very good, easy software and performance is very good.

-

Muhammad Tayyab

★★★★★Post a review on Aug 21, 2022 From UK

Very strong machine, it has brought many new clients to my firm, and I would recommend it to anybody interested in entering the sign area.

-

Ermal Alushi

★★★★★Post a review on Aug 21, 2022 From Italy

The trim cap channel letter bender machine BEL-A200 is operational, but we do not have technical help at this time.

-

Josef Helmlinger

★★★★★Post a review on Aug 21, 2022 From Chile

The machine functions properly. I’ll recommend it to my friends.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From Spain

I’m delighted and grateful to you and your business for your excellent letter-bending equipment.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From France

Let me add that we have been utilizing the machine very effectively. Due to the epidemic, we haven’t been able to use it much, but when we have, we have produced some excellent letters.

-

Ernesto Reyes

★★★★★Post a review on Aug 21, 2022 From USA

Excellent machine. I’d want to thank the supplier for her assistance and support during the purchase process.