Laser Welding Cutting Engraving Marking Protection Goggle

| Category | Laser Parts & Accessories |

| Model No. | BST Laser |

| Views | 48700 |

| Rating | ★★★★★ |

| Price Range | US$20 – US$60/PC |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Leading Time | 3-5 Days |

| Shipping | Sea/Train/Truck/Air |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

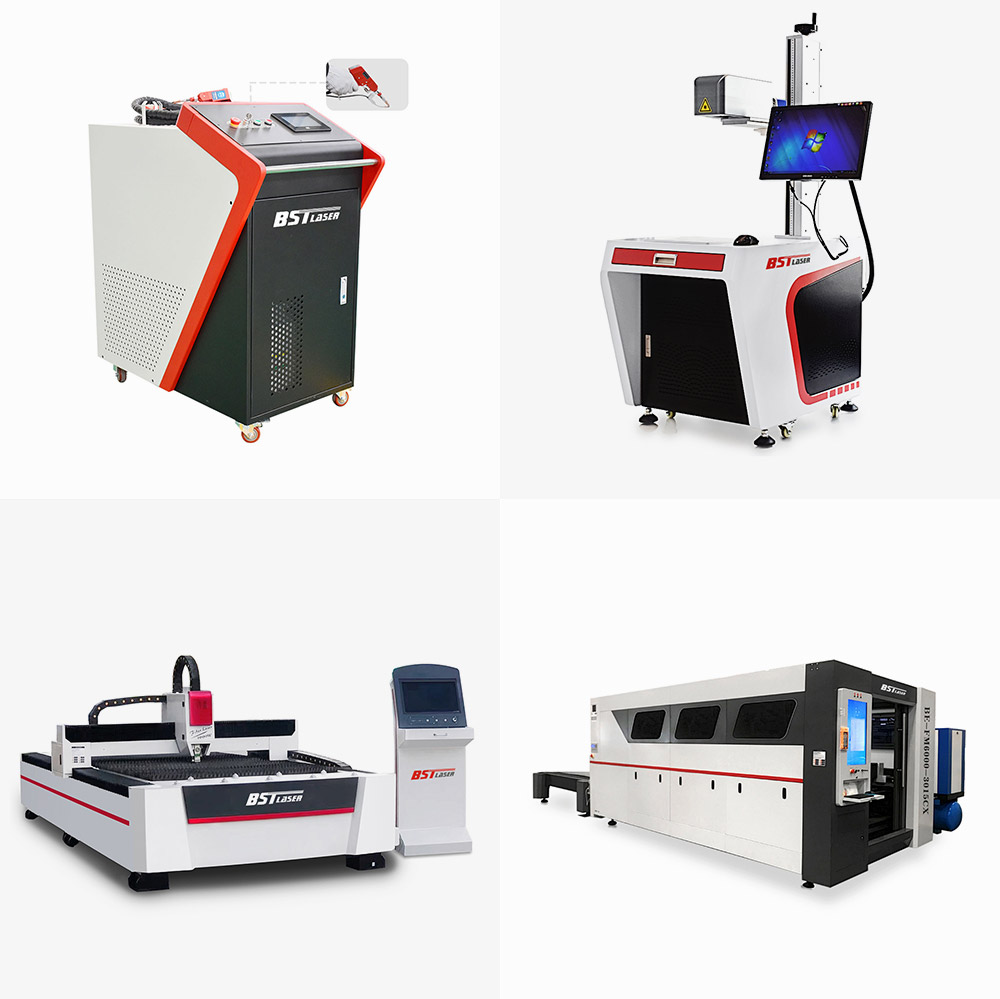

Laser welding cutting engraving marking protection is a powerful and reliable tool that allows you to quickly and accurately create designs, engravings, and cuts in a variety of materials. This technology has a wide range of benefits, including increased cost savings, improved safety, and the ability to produce complex shapes and designs with ease. By utilizing the latest laser technology, manufacturers are able to produce a wide range of parts and components with great accuracy and repeatability.

Laser welding, cutting, engraving, marking, and protection are all processes that can be used to make precision parts with great accuracy and repeatability.

Laser Safety Glasses Selection Guide:

- Laser parameters include the laser’s output wavelength and power density.

- Optical Density (OD): The higher the OD value, the more effective the laser protection glasses are.

- Visible Light Transmittance (VLT): The VLT value is lower than 20%, and the laser safety glasses need to be used in a well-lit area.

- Frame: Whether or not to wear myopia glasses, as well as facial contour.

Good Features

- The light source cannot be changed, and it can safely shield all types of diffuse reflection light.

- The rate of attenuation is high.

- The look is not frightened of wear and tear, and even if there are scratches, they do not impair the safety of light protection.

- The light responds quickly (10-9 seconds).

Application

Laser welding, cutting, engraving and marking are all essential tools in a wide range of industries and applications. Laser welding is used to permanently join two pieces of metal together, while laser cutting and engraving are used to cut, etch or engrave a variety of materials including plastics, metals, and even glass. This technology combines laser welding, cutting, engraving and marking processes into one and is being used to create high-quality products quickly and accurately.

| Laser Wavelength | 1064nm |

| Transmittance | 40% |

| O.D | 740 – 1100nm O.D 5+ | 780 – 1070nm O.D7+ |

| L-Rating | 740 – 1100nm DIR LB5 | 800 – 1070nm IR LB7 |

| Protection Range |

755nm, 808nm,980nm,1064nm etc., |

| Application | Alexandrite, Semiconductor and ND:YAG Laser Protection |

-

Joel Raurell Bravo

★★★★★Post a review on Aug 21, 2022 From Canada

The glasses are very cost-effective, the material is also quite good, and it is very comfortable to wear.

-

Jose Armando Diaz Guevara

★★★★★Post a review on Aug 21, 2022 From Mexico

Very good quality, it can be welded, welded, and cut without attracting attention.

-

Alegria gonzalez

★★★★★Post a review on Aug 21, 2022 From Sweden

The company’s own use and equipped with a laser machine to ship to clients, the packaging is good, and the self-use is also very good. In the future, I’ll go with this one.

-

VASILIS PAPATHANASIOU

★★★★★Post a review on Aug 21, 2022 From Greece

Very affordable, quick arrival, high quality, clear and not dazzling, great.

-

Marcelo Leon

★★★★★Post a review on Aug 21, 2022 From Peru

I frequently shop here since the quality is high and the delivery is quick.