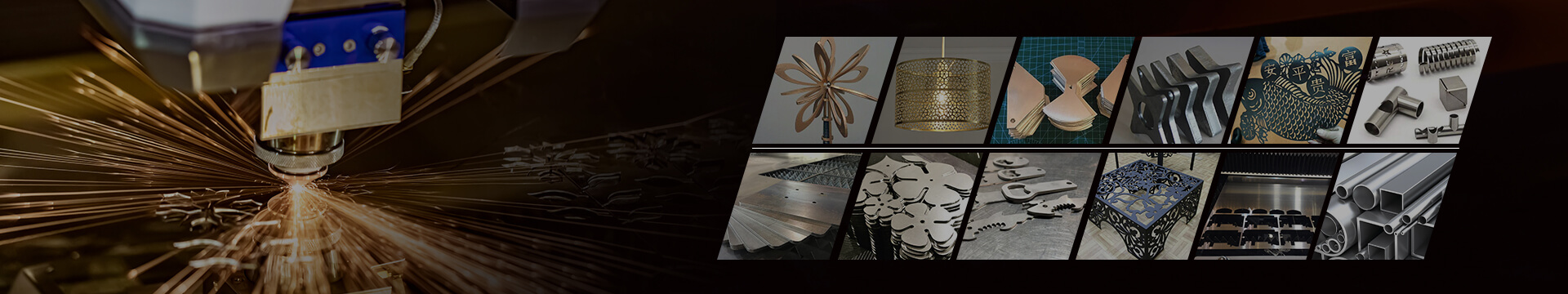

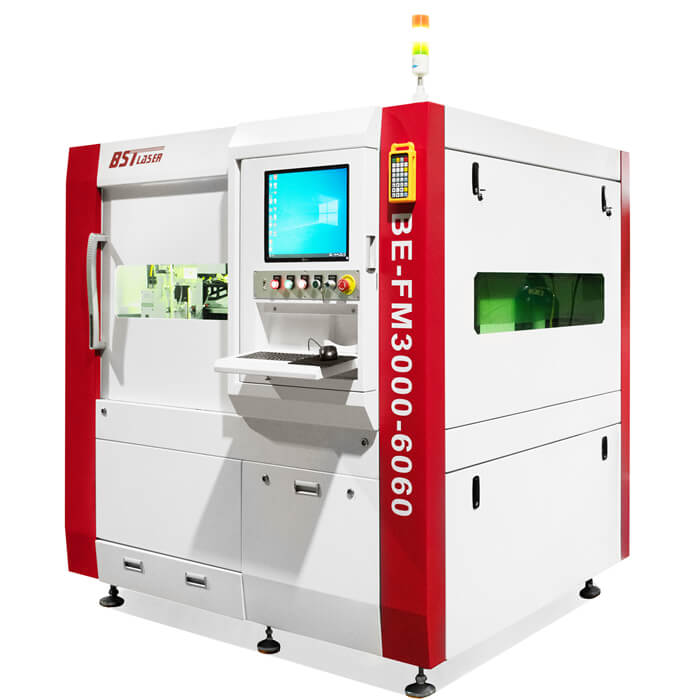

Precision Small Size Fiber Laser Metal Cutting Machine

| Category: | Fiber Metal Laser Cutting Machine |

| Model No.: | BE-FM3000-6060 |

| Views: | 4800 |

| Rating: | ★★★★★4.9/5 Based on 4600 Votes |

| Price Range: | US$12,000 – US$30,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer |

| Leading Time: | 30-45 Days |

| Shipping: | Sea Shipment |

| Warranty Period: | 36 Months for Machine and 24 Months for Fiber Laser Device with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

small fiber laser cutter for metal is designed for sheet metal cutting, with a working area of 600×600mm and optional powers of 1500W 2000W and 3000w . It has efficient and precise cutting performance and is suitable for a variety of metal materials such as stainless steel, carbon steel, and aluminum. The machine adopts advanced fiber laser technology, with fast cutting speed, low energy consumption, and stable operation, which is suitable for a variety of application needs in small and medium-sized processing plants and metal manufacturing industries. It is easy to operate and equipped with an intelligent control system to ensure cutting quality and production efficiency, helping users improve productivity and reduce operating costs.

Precision tiny size fiber metal laser cutting machine with high processing precision, appropriate for gold and silver jewelry processing, precision instruments, and electronic communication equipment. having small compact size which can assist client save much space and shipping freight.

STANDARD COMPONENTS

◆ CYPCUT®FSCUT2000 CNC Control System

◆ Fuji®High Dynamic EtherCAT servo drive

◆ BSTLASER®Dynamic System 4.0:1.5g Acceleration

◆ BSTLASER@Fast Piercing 2.0:Ultra Perforation

◆ Automatic Table Exchanger 1390 (Optional 6060,6040)

◆ Smoke Extraction Fan System

◆ Fiber Laser Source Raycus 1500w 2000w 3000w

◆ Class IV safety system and CE marking

◆ CYPCUT@Embedded Pcs: Industrial PCs with directly integrated I/O level

◆ Hiwin@High performance and high accuracy rack and pinion system

Metal Cutting Capacity

| Laser Power | 1000W | 1500W | 2000W | |

| Nominal power | kw | 1 | 1.5 | 2 |

| Power requirement | kw | 7 | 7 | 8 |

| Wavelength | nm | 1074 | 1074 | 1074 |

| Carbon steel | mm | 10 | 16 | 20 |

| Stainless steel | mm | 5 | 6 | 8 |

| Aluminum Alloys | mm | 3 | 4 | 6 |

| Brass | mm | 2 | 2.5 | 5 |

Machine Feature:

- Small fiber laser cutter structure uses heavy-loading bases of industrial-use grade. All components are 100% guaranteed to be of the highest quality, original, and authentic. If they are discovered to be false, they may be returned.

- The transmission system employs a bridge gantry type middle drive structure, a double rack servo drive, and high inertia high torque Japan Fuji servo motors. High speed and high precision operation are guaranteed by Taiwan’s high-precision rack and reducer, whose maximum acceleration is 0.8G.

- The machine’s body is constructed from a gantry made of aluminum and a thicker cast iron structure. Milling and additional annealing have been used to successfully remove stress from the strong base.

- It uses a high-precision laser cutting head with auto-focusing and a fiber laser generator of renowned international excellence. The lifespan of a fiber laser generator is over ten years, with nearly no consumables and no maintenance required.

- Full closed loop control for a high performance laser cutting control system.

- Industrial linear module system with Z-axis precision.

- An independent control cabinet, an industrial machine tool foot, and a robust towline cable are all standard features.

- Electric components made to European electrical standards and branded for France.

Parts Introduction

Machine Body

- Using a heavy-duty square tube welding construction with an 8mm thickness and a suitable structural design.

- European Standard Design and compact size

- The machine body has a robust structure, good stiffness, and high dynamic responsiveness, and can guarantee stability and non-deformation for 50 years.

Raytools Cutting Head

-

We choose high-precision and high stability lasers to ensure cutting accuracy and effectiveness.

-

Auto Focusing and out putting laser beams, which directly affects the accuracy and quality of cutting.

-

Thin and powerful laser beam achieve precise cutting of materials.

Raycus Laser Source with CE

- Raycus CE Fiber Laser Source(Global Warranty),save after sales service .

- Core component of laser cutting machines, generating laser beams.

Thicken Marble Working Table

-

Placing materials to be cut, which have sufficient rigidity and stability

-

It ensures the materials do not move or deform during the cutting process and keep over 30 years without deformation.

-

High precision reach 0.1mm and advanced cutting than common.

Ball Screw Transmission

XYZ axis all adopts ball screw transmission and linear guide rails, which ensures high rigidity and stability.

Cypcut Controlling Software

Upgrade version controlling system specially built for the sheet metal fabrication sector, with features such as ease of installation and adjustment, outstanding performance, and completely integrated solutions.

Built-in Controller for 180 Degree

- Machine is with built in LCD controller which can move 180 degree freely which make the operation flexiable

- Well Installed Software and Adjusted Parameters for Direct Usage

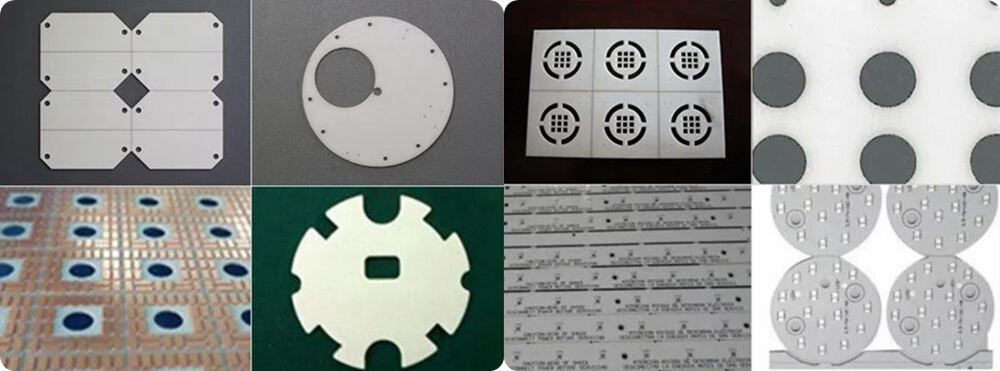

Application

The application of fiber laser metal cutting technology has grown dramatically in recent years. This technology gives increased precision and enhanced cutting quality compared to the older methods. Fiber laser cutting is a speedy and effective way to cut metal, and it is becoming increasingly popular in the metal fabrication business.

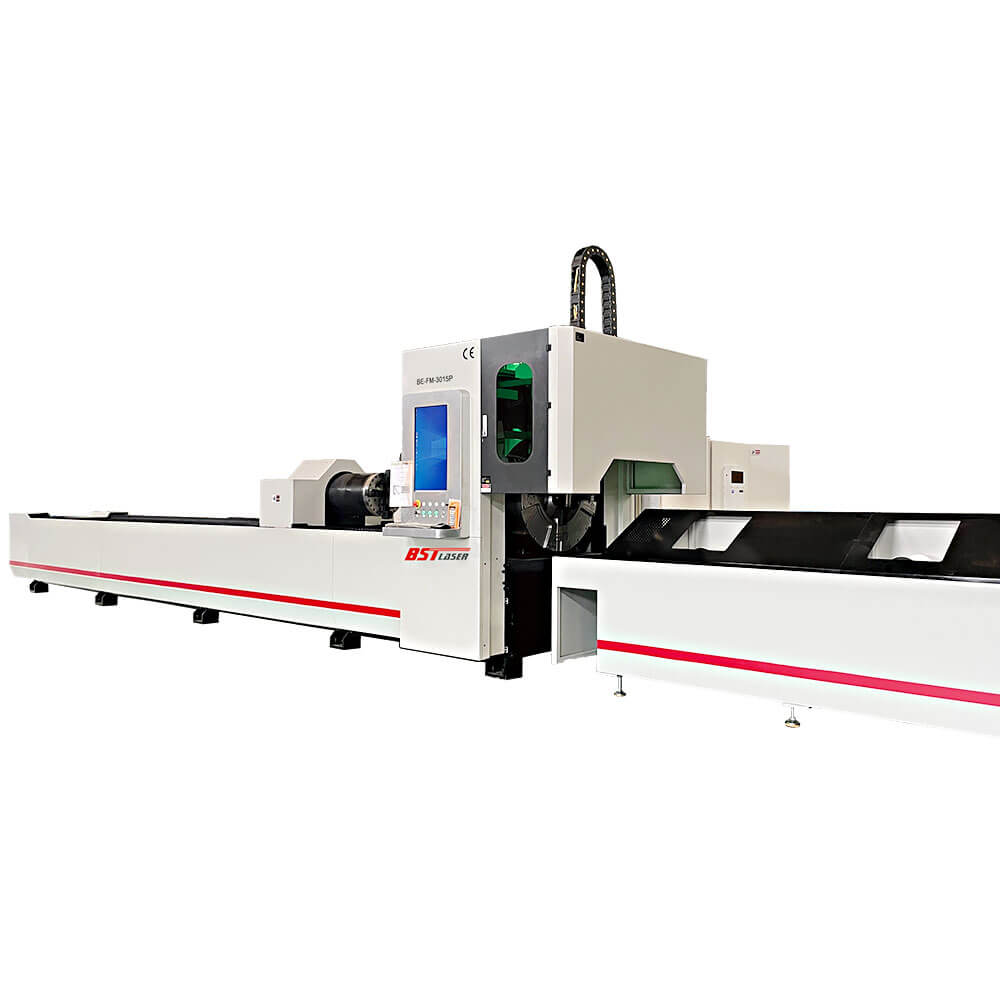

It is excellent for fast cutting of stainless steel, carbon steel, manganese steel, copper plate, aluminum plate, galvanized plate, various alloy plates, rare metals, and other materials and can cut a range of metal plates, ceramics, and pipes.

Covered industries: sheet metal, jewelry, glasses, machinery and equipment, lighting, Digital products, electronic components, computer accessories, instrumentation, precision equipment, auto parts, craft gifts, etc. Chemical industry.

Optional Items

| Model | BE-FM-1390S | BE-FM-6060S | BE-FM-6040S |

| Working Size | 1300×900mm | 600×600mm | 600×400mm |

| Laser Power | 1500w 2000w 3000w 6000w | ||

| Laser Source | Raycus (Optional: Max / Reci / IPG) | ||

| Laser Technology | Germany Technology | ||

| Optional Size | 4000×1500mm/6000×1500mm/4000×2000mm/6000×2000mm | ||

| Max. Cutting Speed | 30-50 Meters / Min (up to materials) | ||

| Max. Location speed | 60m/min | ||

| Laser wavelength | 1070nm | ||

| Minimum line width | ≤0.1mm | ||

| X/Y Location Accuracy | 0.03mm | ||

| Re-location precision | ±0.02mm | ||

| Max Acceleration | 0.8G | ||

| Max. moving speed | 100m/min | ||

| Supporting Format | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc | ||

| Power demand | 3 PHASE AC 380V 50HZ/60HZ | ||

| Cooling Way | Water Cooling | ||

| Worktable max. load | 2000KGS | ||

| Transmission Method | gantry type double rack servo drive | ||

| Table-driven system | Japanese Imported Servo Motor & Driving System | ||

| Focus Method | Following and Automatic Adjust Focus | ||

| Control software | Cyprus/NC Studio | ||

| Working Environment Temperature | 0℃~45℃ | ||

| Working Environment Humidity | 5%~95% non-condensing | ||

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-FM3000-6060 | 190cm×165cm×198cm, 6.207CBM | 1200KG |

|

|

|

| Inside layer is covered by thickening plastic bag and foam for waterproof. | Compound Wooden cases which comply with Export Package Standard | Send to the named sea port and load in the container |

-

Philip Im

★★★★★Post a review on Aug 21, 2022 From Korea

The design is really attractive but sturdy, and the cutting precision is considerably higher than the big size 3015 that I previously purchased. I fell in love with it at first sight.

-

Sangho Yi

★★★★★Post a review on Aug 21, 2022 From Korea

We are really pleased with the laser and motion, and definitely recommend it to clients.

-

Salvatore marrapesa

★★★★★Post a review on Aug 21, 2022 From Italy

Everything is operating well now, and the cutting is excellent. We may still require some technical support during testing, but all issues have been resolved.

-

UAE

★★★★★Post a review on Aug 21, 2022 From Hadhrat Ali

Without any technical assistance, we can put the equipment together and test it using your instruction booklet and training video.

-

Miguel A Hernandez

★★★★★Post a review on Aug 21, 2022 From USA

Good company, fast and veary good service. like always great product.

-

Jose Eduardo Paris Muñoz

★★★★★Post a review on Aug 21, 2022 From Brazil

Always good work. with lot of instructions… technical service is very good… I m very happy to ov laser, it’s my 8th machine I have order to them.