1KW 1.5kw 2kw SS Aluminum Handheld Fiber Laser Welder

| Category | Auto Laser Welding Machine |

| Model No. | BE-WF1500M |

| Views | 56300 |

| Rating | ★★★★★4.9/5 Based on 1000 Votes |

| Price Range | US$4199-US$7999/set |

| Payment Term | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Production Time | 5-7 Days |

| Shipping | Air/Sea/Train/Truck |

| Warranty Period | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

Fiber laser welding machine adopts the latest advanced fiber lasers and equipped with wobble handheld welding gun to realize handheld welding. It has the advantages of simple operation, high accuracy welds, fast welding speed and no consumables. It can weld thin stainless steel plates, iron plates, galvanized plates and other metal materials, and can perfectly replace traditional argon arc welding, electric welding and other processes. The hand-held fiber laser welding machine can be widely used in complex and irregular welding processes in cabinets, kitchens, stairs, elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel homes and other industries.

The working mode of the hand-held optical fiber laser welding machine is hand-held welding, flexible and convenient, and the welding distance is longer.

The portable optical fiber laser welding equipment replaces the fixed optical path with a hand-held welding gun and is primarily used for laser welding of long-distance and large work items. The heat affected region during welding is limited, therefore there will be no deformation, blackening, or pores on the back.

Good Features

◆ Wide Welding Range

The handheld welding head is equipped with 10m original optical fiber, which overcomes the limitation of workbench space and can weld outdoors and remotely.

◆ Convenient and Flexible Use

Handheld laser welding is equipped with wheels, allowing it to move freely and modify its direction at any moment, and it does not require fixed stations. It is free and adaptable, making it suited for a variety of working situations..

◆ A variety of welding methods

It can do stack welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, and so on. Larger work items with irregular shapes and varied complex welds can be welded by this machine. Welding at any angle is possible. It can also clean and cut. Cleaning and cutting may be exchanged easily by simply switching the welding copper nozzle with the cutting copper nozzle, which is quite handy.

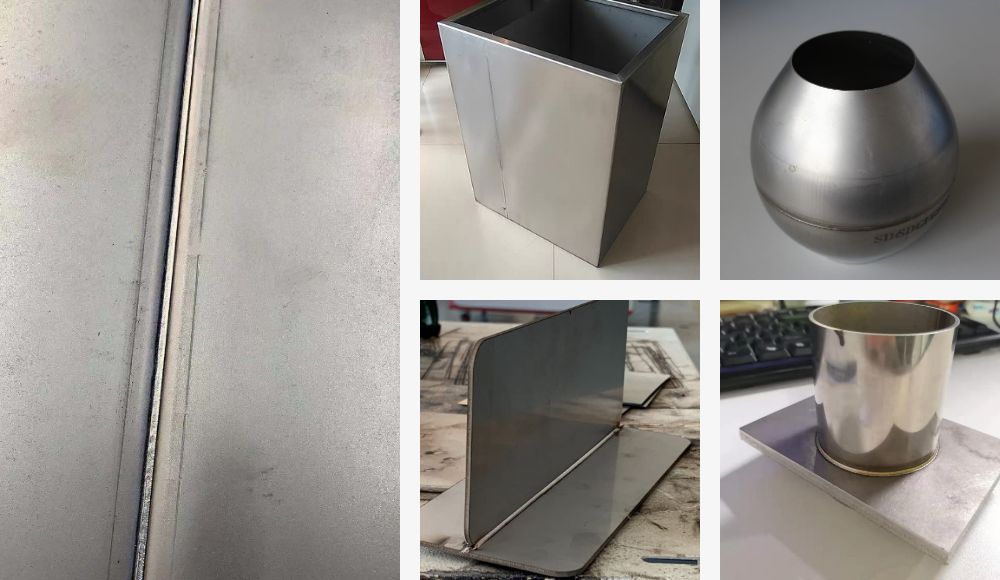

◆ Good Welding Effect

Hot melt welding is done with a handheld laser. Laser welding has a higher energy density and can achieve a better welding effect than traditional welding. The welding region has a low heat effect, is difficult to distort or blacken, and has no pores on the back. It can accomplish deep welding because full melting is firm and reliable, and the weld strength reaches or even exceeds the base metal itself, which regular welding machines cannot complete.

◆ No Need Polishing

Traditional welding requires polishing to maintain smoothness. Hand held laser welding is continuous welding that is smooth without fish scales, beautiful without scars, and does not require any after-grinding.

◆ No Consumables

The welding can be easily completed, and no consumables and almost free of maintenance

◆ Multiple Safety Alarms

The switch is only activated when the welding tip comes into contact with metal. When the work piece is removed, the light automatically locks, and the switch is equipped with body temperature sensor. High safety, ensuring operator safety while working.

◆ Labor Cost Saving

Processing costs can be decreased by 30% when compared to arc welding. The procedure is straightforward and simple to learn, and the operator’s technical threshold is low. Ordinary workers can weld after a short training period and get high-quality welding results.

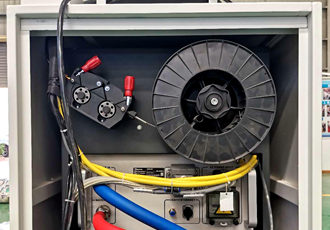

Parts Introduction

Whole Machine Structure

- Designing with industrial integration and European standards in mind.

- Compact and attractive structure, good beam mode, concentrated energy, stable performance, dependable use, quick welding speed, wide range of suitable welding, long service life, and so on.

- Different choices for E,T,G,M.

Fiber Laser Source

- China’s best No. 1 continuous fiber laser source, with powerful laser beam and continuous welding capability, lifetime of over 10 years, no consumables, and no maintenance required.

- Fiber laser sources from Raycus, Max, JPT, BWT, and Reci are available.

Adopt Famous Brand Fiber Transmission

- Fast speed, consistent beam transmission, lowest consumption, and most powerful, thanks to Japan-imported fiber cable.

- The ideal length for long-distance welding is the standard 10m (alternative lengths are 15m and 20m).

Controlling Button

- Separate press buttons for normal operation (Emergency, Key Switch, Laser Button, and Power Button) are extremely useful.

- Simple to use and eliminates the possibility of errors.

G Design Swing Welding Gun

- Weight: 0.8kg, Industrial and Technology

- Adjustable Laser Beam Size: 0.5-5mm

- Language: Chinese, Chinese, English, Russian, Vietnamese, Korea

- 6 Wobble Modes(spot, line, double circle, triangle, double triangle)

- Double Swing Motors

S Design Swing Welding Gun

- 3 in 1 Multifunctional (Auto Welding+Cutting+Cleaning)

- Weight: 0.8kg, Powerful and Light

- Languages: Chinese, English, Korean, Russian, Japanese, French, German, Latin, Traditional Chinese, Italian, Spanish, Romanian, and Polish

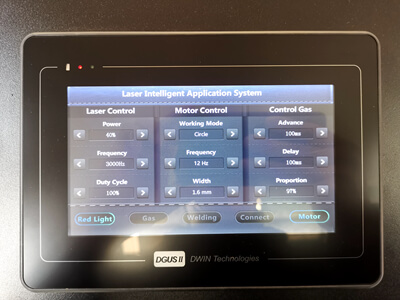

Controlling System

- High sensitivity, built-in software and LCD touch screen controller, supports Chinese, English, Russian, Spanish, and Korean, among other languages.

- Simple, user-friendly interface that genuinely reflects what you see is what you get.

Industrial Water Cooling System

- Installed with a top China brand Hanli or S&A constant temperature industrial water cooling system that can automatically regulate the temperature.

- Integrated design that saves the client a lot of space and money on shipping.

- We use a 1.5P water chiller for the inner water chiller, and the maximum water flow rate is 3.3L/minute.

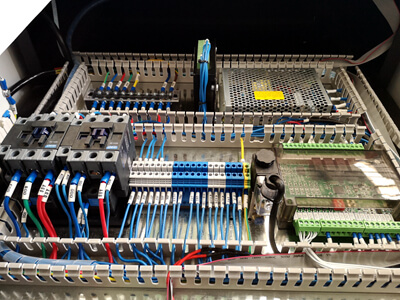

European Standard Electric Parts

- The electric control parts have a precise design, an integrated circuit board, and a clear architecture that allows categorization to be defined simply.

- Strong and weak currents are separated, there is no interference, and the current is stable.

Application

Aluminum handheld fiber lasers are a powerful and versatile tool with a wide range of applications. From industrial manufacturing to medical uses, these lasers offer users the ability to cut, weld, and mark materials quickly and precisely

It is widely used in the kitchen and bathroom industries, the household appliance industry, the advertising industry, the mold industry, the stainless steel door and window industry, the handicraft industry, the household goods industry, the furniture industry, the auto parts industry, and so on.

Optional Items

| Model | BE-WF1000M |

| Laser Running Mode | Continuous/Modulate |

| Beam Quality | M2<1.2 |

| Power | 1000W 1500W 2000W 3000W |

| Line Width | <5nm |

| Laser Device | IPG/Raycus/Max/BWT/CAS Laser |

| Power Consumption | 6kw |

| Spot Size | 0.1-5mm |

| Pulse Width | 0.1-20ms |

| Welding Depth | 0.5-3mm |

| Welding Connector | QBH |

| Fiber Cable Length | 10m (Optional: 15m) |

| Laser Wavelength | 1070nm |

| Position | Red Pointer |

| Continuous Working | 24 hours |

| Cooling System | Industrial Constant Chiller System |

| Working Temperature | 15-35℃ |

| Input Voltage | AC220V±10%,50HZ/60HZ |

| 1000w Fiber Handheld Maximum Welding Depth | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | |||||

| Iron | ● | ● | ● | ● | ● | |||

| Mild Steel | ● | ● | ● | ● | ● | |||

| Aluminum | ● | ● | ||||||

| Brass | ● | ● | ||||||

| 1000w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | |||||

| Galvanized Sheet | ● | ● | ||||||

| Iron | ● | ● | ● | |||||

| Mild Steel | ● | ● | ● | |||||

| Aluminum | ● | |||||||

| Brass | ● | |||||||

| 1500w Fiber Handheld Maximum Welding Depth | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ● | |||

| Galvanized Sheet | ● | ● | ● | ● | ● | |||

| Iron | ● | ● | ● | ● | ● | |||

| Mild Steel | ● | ● | ● | ● | ● | |||

| Aluminum | ● | ● | ● | |||||

| Brass | ● | ● | ||||||

| 1500w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | |||||

| Iron | ● | ● | ● | ● | ||||

| Mild Steel | ● | ● | ● | ● | ||||

| Aluminum | ● | ● | ||||||

| Brass | ● | ● | ||||||

| 2000w Fiber Handheld Maximum Welding Depth | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ● | ● | ||

| Galvanized Sheet | ● | ● | ● | ● | ● | |||

| Iron | ● | ● | ● | ● | ● | ● | ||

| Mild Steel | ● | ● | ● | ● | ● | ● | ||

| Aluminum | ● | ● | ● | ● | ||||

| Brass | ● | ● | ||||||

| 2000w Fiber Handheld Welding Penetration Thickness | ||||||||

| Thickness Materials | 1mm | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 10mm |

| Stainless Steel | ● | ● | ● | ● | ||||

| Galvanized Sheet | ● | ● | ● | ● | ||||

| Iron | ● | ● | ● | ● | ||||

| Mild Steel | ● | ● | ● | ● | ||||

| Aluminum | ● | ● | ● | |||||

| Brass | ● | ● | ||||||

Package and Shipment

| Model | Package Size | Gross Weight |

| BE-WF1000M | 1.2m×0.73m×1.27m, 1.13CBM | 260KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craftcase. |

-

Vova Boyko

★★★★★Post a review on Aug 21, 2022 From Russia

Perfect welding seam, far superior than a standard welding equipment. Smooth and firm welding. We are constructing a new plant and will add more units if all goes smoothly.

-

Jose Hernandez

★★★★★Post a review on Aug 21, 2022 From US

The machine works well. Laser welding gun that is lightweight and easy to operate. Our employees are pleased with the machine. Thank you so much, BST Laser!

-

Stephanie Lunder

★★★★★Post a review on Aug 21, 2022 From Canada

Very professional. This machine can do welding, cleaning and cutting. It really beyond our expectation. No need after polishing and sanding.The machine so amazing!

-

Pramod Mahato

★★★★★Post a review on Aug 21, 2022 From Australia

The machine is used to weld stainless steel. The welding speed is extremely quick. It could save three welders’ jobs and save us a lot of money! Thank you for developing new laser technology!

-

Ana Garcia

★★★★★Post a review on Aug 21, 2022 From Spain

Before making a purchase, we conduct extensive research. There are numerous options on the market, each with its own set of benefits. We had never used such a machine before, so we were a little concerned at first, but we soon discovered that BST is very professional and provides fantastic after-sales care. Buy with confidence!

-

Mohammed Makki

★★★★★Post a review on Aug 21, 2022 From UAE

It is unquestionably faster than argon welding. The welding seam is excellent and can withstand greater pressure. Workers are at ease!

-

choi yunje

★★★★★Post a review on Aug 21, 2022 From Korea

The machine matches the seller’s description. It is simple to use and does not require any special expertise. After 30 minutes of training, workers may operate the equipment. It is the correct machine that we require!